In the competitive world of ceramic manufacturing, every kiln performance decision impacts production output, product consistency, and long-term profitability. One often-overlooked but critical factor is the choice of refractory lining—specifically, high-performance alumina bricks (also known as corundum bricks). These materials aren’t just another component—they’re a strategic investment in operational resilience.

Ceramic kilns operate at temperatures exceeding 1,300°C, exposing internal linings to extreme thermal shock, chemical erosion from glazes and fluxes, and mechanical wear from material movement. Traditional fireclay or silica bricks typically last only 6–9 months under continuous operation before showing signs of degradation—leading to frequent shutdowns, inconsistent firing results, and increased scrap rates.

A case study from a mid-sized tile manufacturer in Italy revealed that switching from standard fireclay bricks to high-purity alumina bricks reduced kiln downtime by 40% over six months and improved first-pass yield from 87% to 95%. This isn't an isolated success—it reflects what happens when you match the right refractory to the process.

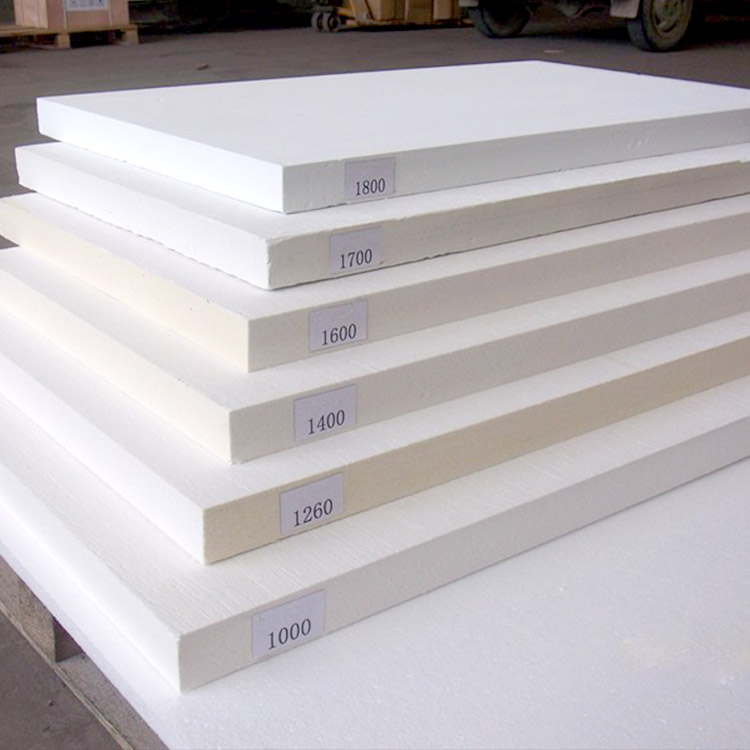

High-grade alumina bricks offer unmatched properties:

These characteristics directly translate into fewer kiln repairs, more consistent heat distribution, and less variability in final product quality—key metrics for any B2B buyer evaluating ROI on refractory upgrades.

For ceramic producers aiming to scale efficiently—or simply maintain stable operations—alumina bricks are not optional. They reduce maintenance costs by up to 30%, extend kiln life by 2–3 years, and significantly improve defect-free output. In industries where margins are tight, this kind of performance gain can mean the difference between profit and loss.

Whether you're running a small artisan studio or a large-scale porcelain plant, choosing the right refractory material ensures your kiln doesn’t become a bottleneck—it becomes a competitive advantage.

Get a free technical assessment tailored to your ceramic production line and discover how alumina bricks can boost efficiency, reduce waste, and increase your bottom line.

Download Our Refractory Selection Guide