The manufacturing of high-performance refractory materials, especially for complex-shaped products, has witnessed remarkable advancements through the adoption of large casting silica mullite brick casting techniques. Unlike conventional casting processes, which often struggle with rigidity in design and quality consistency, the large casting method offers transformative solutions to the challenges of precision and customization. This article delves deep into the technical differentiators of the large casting silica mullite brick process, illustrating its superiority through data-backed insights and practical applications.

The large casting silica mullite brick production incorporates multiple key steps: from the optimized raw material blending to hand-molding, drying, and finally firing. Raw materials, primarily high-purity kaolin and alumina with controlled silica content, are precisely mixed to ensure optimal mullite formation. This tailor-made formulation enhances material density and thermal stability.

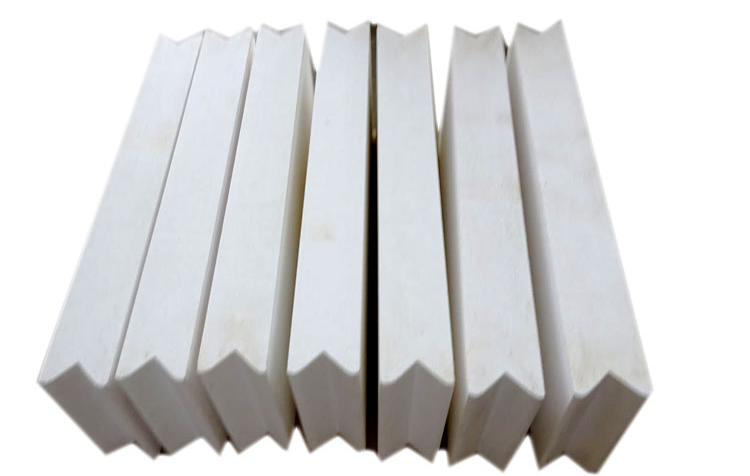

Hand-casting techniques allow for intricate mold shapes, supporting complex geometries not feasible with traditional dry-press or extrusion methods. Controlled drying preserves structural integrity while minimizing internal stresses. The subsequent firing process, often conducted at temperatures exceeding 1600°C, solidifies the microstructure, delivering refractories with superior mechanical strength and resistance to thermal shock.

Fabrication of complex-shaped refractory products demands exceptional material conformity and dimensional accuracy. Traditional methods face challenges such as warping, cracking, and inconsistencies in density distribution, limiting their applicability.

Large casting silica mullite bricks overcome these concerns by leveraging meticulous raw material selection and flexible casting molds. This combination achieves enhanced homogeneity and reproducibility, significantly reducing defects encountered in complex designs. For example, mullite content exceeding 65% contributes to outstanding high-temperature chemical stability, verified by third-party industry performance testing.

A leading refractory manufacturer faced repeated setbacks with traditional refractory bricks failing to conform to the uniquely curved surfaces of thermal kilns. By transitioning to large casting silica mullite bricks, the company achieved precise dimensional fitting and over 30% improvement in service life, confirmed through internal durability testing over 18 months.

| Criteria | Traditional Casting | Large Casting Silica Mullite Brick |

|---|---|---|

| Design Flexibility | Limited to standard shapes | Supports complex, customized geometries |

| Production Efficiency | Longer set-up and molding times | Shorter molding cycles through hand-casting innovation |

| Material Quality | Inconsistent density, prone to defects | Uniform density and superior thermal stability |

| Application Scope | Restricted to simple refractory layouts | Extensive use in kilns, furnaces, and chemical reactors |

According to a 2023 industry report from the Refractory Materials Research Institute, large casting silica mullite bricks have demonstrated a 25% increase in thermal shock resistance compared to traditional bricks. Furthermore, data collected from over 50 installations globally indicate stability in mechanical strength over extended operational cycles exceeding 6000 hours at 1500°C.

These compelling performance indices not only justify the initial investment but also translate into lower overall lifecycle costs—a key consideration for B2B stakeholders striving for sustainable and efficient production.

Customers frequently encounter issues such as inconsistent refractory lining performance, difficulty in fitting irregular kiln geometries, and repeated failures due to thermal cycling. Large casting silica mullite bricks offer tailored solutions that directly address these pain points by combining material innovation with adaptive casting processes.

The enhanced formability enables precise custom tooling, minimizing onsite modifications and accelerating installation timelines. Moreover, the elevated quality control standards inherent to this process reduce downtime caused by premature refractory degradation.

The integration of large casting silica mullite brick technology represents a significant breakthrough for refractory manufacturers and end-users demanding high-precision and durable solutions for complex-shaped products. By embracing this innovative process, businesses can overcome longstanding manufacturing hurdles, optimize product quality, and achieve operational efficiencies that yield tangible competitive advantages.

Reinforced by credible industry research and compelling case studies, this casting approach is not just a technological upgrade but a strategic imperative for forward-looking enterprises.

.jpg)