Industrial equipment is constantly exposed to extreme conditions such as high temperatures and corrosive environments. These challenges can lead to significant wear and tear, reducing the lifespan of critical components and increasing maintenance costs. In industries like glass manufacturing and steel production, the need for durable and reliable materials has never been more urgent.

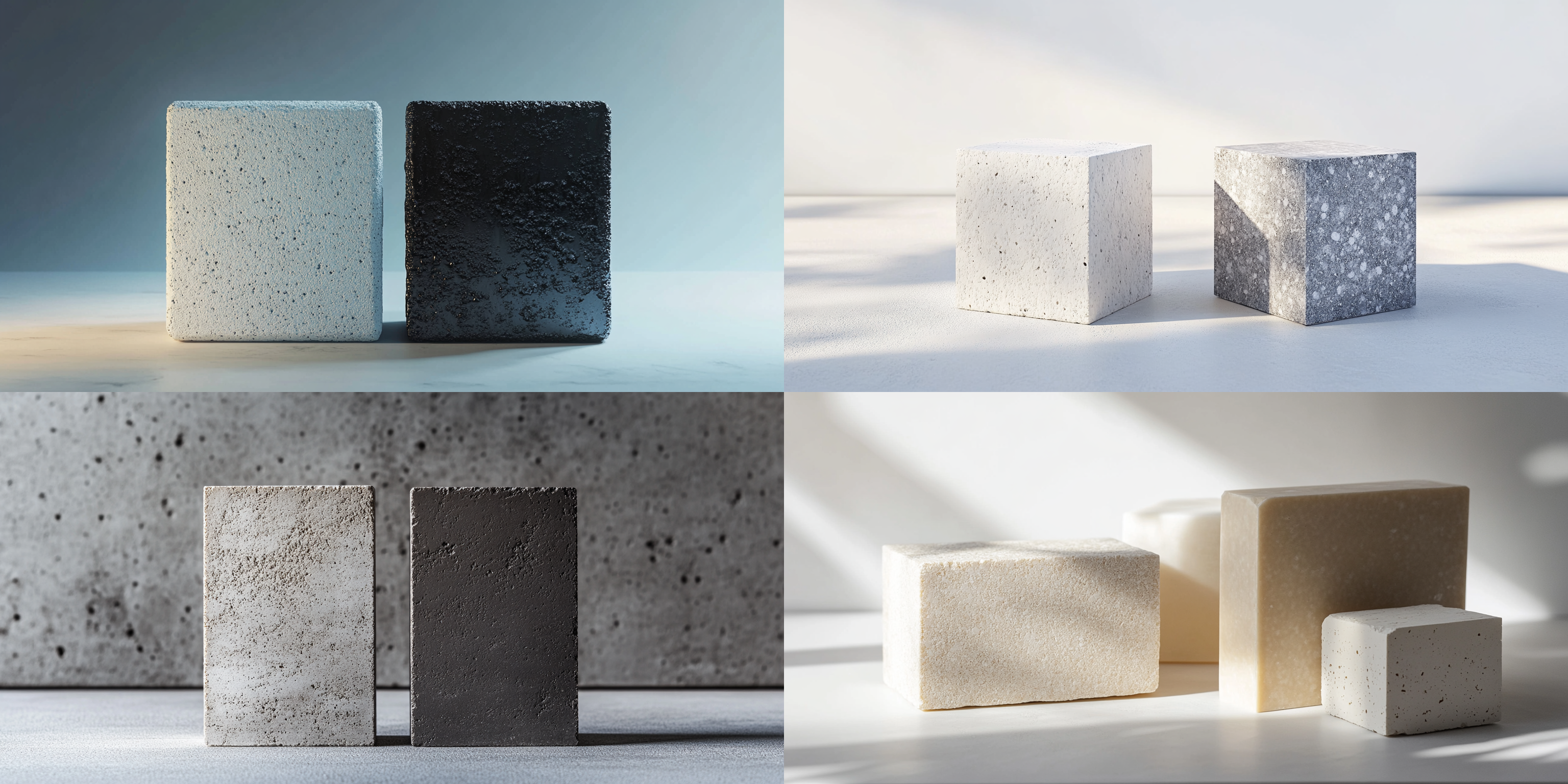

Corrosion-resistant sillimanite bricks are a game-changing solution designed to withstand the harshest industrial conditions. Made from natural sillimanite minerals, these bricks undergo a high-temperature firing process that transforms them into mullite and free silica. This transformation gives them exceptional properties, including a high refractory temperature of 1770–1830°C and a load softening temperature of 1500–1650°C.

The unique composition of sillimanite bricks ensures excellent thermal shock resistance, low thermal expansion, and superior erosion resistance. These features make them ideal for use in demanding applications such as glass furnaces and blast furnace linings, where traditional materials often fail under prolonged exposure to heat and chemical attack.

Below is a summary of the key performance characteristics of corrosion-resistant sillimanite bricks:

| Property | Value |

|---|---|

| Refractory Temperature | 1770 - 1830°C |

| Load Softening Temperature | 1500 - 1650°C |

| Thermal Expansion Coefficient | ≤ 0.5% |

| Flexural Strength | ≥ 40 MPa |

| Porosity | ≤ 18% |

One of the most common applications of sillimanite bricks is in glass melting furnaces, where they provide stable insulation and protect the furnace structure from molten glass and combustion gases. In blast furnaces, these bricks serve as lining materials, significantly extending the service life of the furnace and improving operational efficiency.

.jpg)

A case study from a leading glass manufacturer showed that replacing conventional refractory materials with sillimanite bricks reduced furnace downtime by up to 30% and improved product quality by minimizing impurities introduced during the melting process. Similarly, a steel plant reported a 25% increase in furnace longevity after switching to sillimanite bricks for their high-temperature zones.

When comparing traditional refractory materials with sillimanite bricks, the advantages become clear:

| Factor | Traditional Materials | Sillimanite Bricks |

|---|---|---|

| Refractory Temperature | 1600 - 1750°C | 1770 - 1830°C |

| Thermal Shock Resistance | Low | High |

| Maintenance Frequency | High | Low |

| Product Quality Impact | Potential Contamination | Minimal |

| Lifespan | Shorter | Longer |

Sillimanite bricks offer more than just durability—they deliver real business value. By reducing equipment damage risks, improving product quality, and enhancing operational efficiency, these bricks help companies achieve sustainable growth and strengthen their market position. With fewer breakdowns and longer service life, businesses can focus on innovation and customer satisfaction rather than constant repairs.

For global buyers looking for a reliable and cost-effective solution to industrial high-temperature corrosion, sillimanite bricks are the ultimate choice. They not only meet but exceed industry standards, ensuring long-term performance and profitability.

Don’t let high-temperature corrosion compromise your operations. Upgrade to corrosion-resistant sillimanite bricks today and experience the difference in performance, reliability, and return on investment.