Your ceramic enterprise is constantly facing challenges in the high - temperature environment of kilns. High - temperature damage and chemical erosion are the main culprits that lead to short kiln lifespans and numerous product defects. These issues not only increase your production costs but also affect the quality and competitiveness of your products in the market. For example, the average lifespan of a ceramic kiln without proper refractory materials may be as short as 2 - 3 years, and the product defect rate can reach up to 15%.

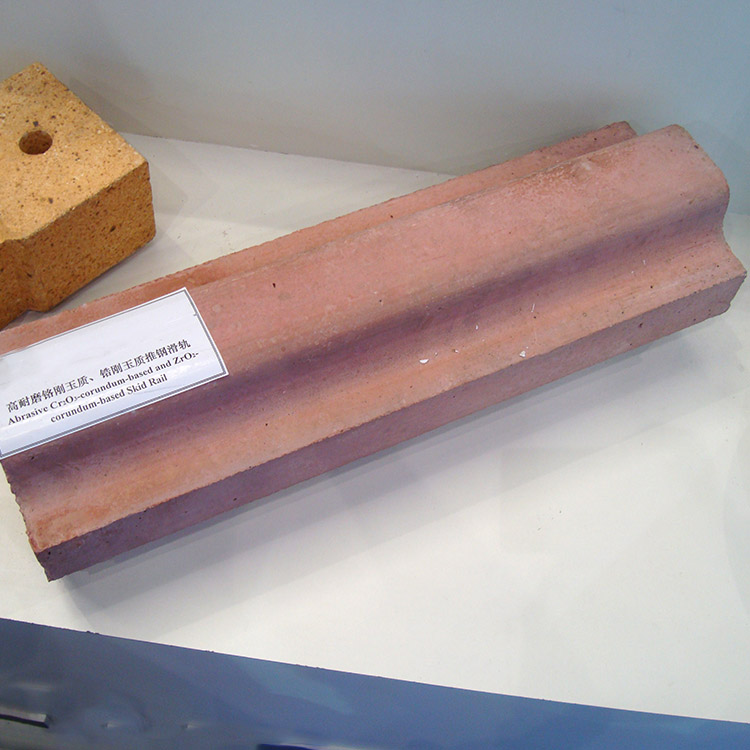

Corundum bricks are here to solve your problems. They possess high wear resistance, corrosion resistance, high - temperature stability, and the ability to resist molten glass erosion. Their high wear resistance ensures that they can withstand the abrasion caused by the movement of materials inside the kiln. In terms of corrosion resistance, they can resist the chemical attack of various substances in the high - temperature environment. Their high - temperature stability allows them to maintain their structure and performance even at extremely high temperatures. For instance, corundum bricks can maintain their integrity at temperatures up to 1800°C.

Many ceramic enterprises, regardless of their scale or production process, have successfully applied corundum bricks. A medium - sized ceramic factory reported that after using corundum bricks, the kiln lifespan was extended by 50%, from 3 years to 4.5 years. Another large - scale manufacturing group saw a 10% increase in the finished product rate, from 85% to 95%. Here is a quote from one of our satisfied customers: "Since we switched to corundum bricks, our kiln has become more reliable, and the quality of our products has improved significantly. It's a great investment."

| Parameters | Corundum Bricks | High - Alumina Bricks | Silica Bricks |

|---|---|---|---|

| Refractoriness | Up to 1800°C | 1600 - 1700°C | 1650 - 1710°C |

| Thermal Shock Resistance | High | Medium | Low |

| Service Life | 4 - 6 years | 2 - 3 years | 1 - 2 years |

| Maintenance Cost | Low | Medium | High |

For small - batch custom production, corundum bricks with high precision can ensure the quality of each product. They can withstand the frequent temperature changes caused by different batches of production. In the case of large - batch continuous firing, corundum bricks' long - term high - temperature stability can guarantee the continuous and efficient operation of the kiln. For special glaze processes, corundum bricks' resistance to chemical erosion can protect the kiln from the damage of special substances in the glaze.

Choosing corundum bricks means choosing long - term stable benefits. It will make your kiln more durable and ensure that every ceramic product is perfect. With corundum bricks, you can reduce your maintenance costs, improve your product quality, and enhance your competitiveness in the market. Don't miss this opportunity to transform your ceramic production. Click here to learn more and make the best choice for your enterprise.