In the ceramic industry, the choice of refractory materials for high - temperature firing kilns is crucial for factories of all sizes. High - temperature refractory corundum bricks are emerging as a top choice for many ceramic manufacturers. This article aims to provide a comprehensive understanding of these bricks and offer customized solutions for different - scale ceramic factories.

Ceramic kilns operate under extremely harsh conditions. They are exposed to high temperatures that can reach up to 1600 - 1800 degrees Celsius and are also subject to strong chemical corrosion from various ceramic raw materials and combustion products. These factors significantly shorten the lifespan of traditional refractory materials and can also affect the quality of ceramic products. For instance, a small - scale ceramic factory experienced a 15% reduction in product quality due to the erosion of refractory materials in their kiln over a 6 - month period.

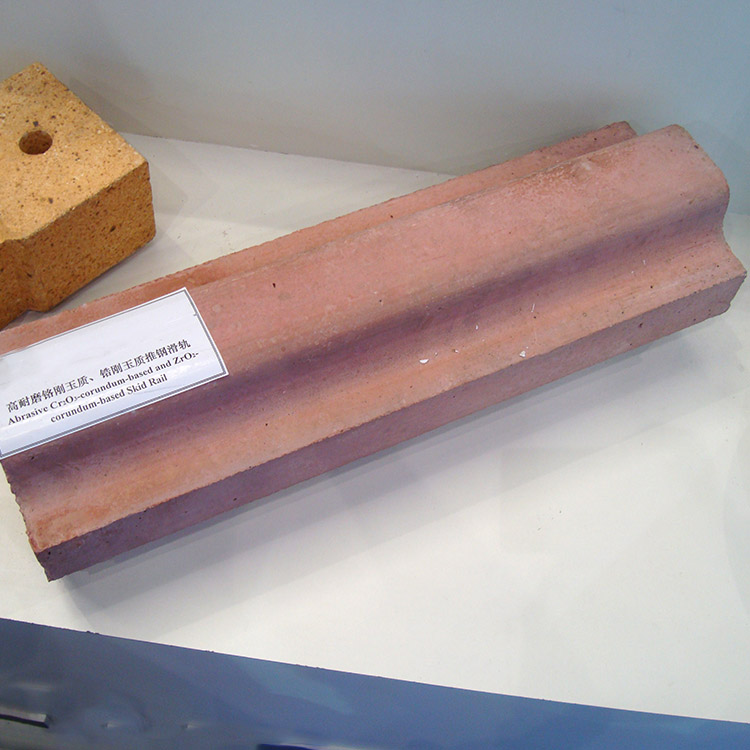

High - temperature refractory corundum bricks are made from high - purity alumina raw materials. They possess excellent physical and chemical properties. Firstly, they have extremely high wear resistance. Tests show that corundum bricks can withstand abrasion from high - speed airflow and solid particles in the kiln for up to 5 - 10 years, while ordinary refractory bricks may need replacement every 1 - 2 years. Secondly, they exhibit strong corrosion resistance. They can resist the corrosion of acidic and alkaline substances in the ceramic firing process. The chemical stability of corundum bricks ensures that they do not react with the ceramic raw materials, thus protecting the quality of the final products.

The superior properties of corundum bricks have a significant positive impact on both the kiln lifespan and ceramic quality. By using corundum bricks, the average lifespan of a ceramic kiln can be extended by 2 - 3 times. This means fewer kiln shutdowns for maintenance and replacement, leading to increased production efficiency. In terms of ceramic quality, since corundum bricks do not contaminate the ceramic products during firing, the rate of defective products can be reduced by 10 - 15%. For example, a large - scale ceramic factory in Italy increased its production efficiency by 20% and reduced its defective product rate from 8% to 6% after replacing traditional refractory materials with corundum bricks.

In several different - scale ceramic enterprises, the use of corundum bricks has achieved remarkable results. A medium - scale ceramic factory in China reported a 12% increase in profit margins after switching to corundum bricks, mainly due to reduced maintenance costs and improved product quality. When compared with other common refractory materials such as clay bricks and magnesia bricks, corundum bricks show better overall performance. Although the initial investment of corundum bricks may be slightly higher, their long - term cost - effectiveness far exceeds that of other materials.

For small - scale ceramic factories, cost - control is a major concern. A cost - effective solution can be to use corundum bricks in the areas of the kiln that are most exposed to high temperatures and corrosion, while using other relatively inexpensive refractory materials in less critical areas. Medium - scale factories can choose high - performance corundum bricks for the entire kiln to improve overall production efficiency and product quality. Large - scale factories, with their high production volumes, should adopt advanced corundum brick solutions to ensure long - term stable production and high - quality products.

Are you looking to enhance the efficiency and quality of your ceramic production? High - temperature refractory corundum bricks can be the game - changer for your factory. Click here for a customized corundum brick solution