When it comes to purchasing refractory materials, you may often find yourself in a quandary. With so many options available in the market, choosing the right one can be a daunting task. Among these refractory materials, mullite bricks stand out as a popular choice due to their excellent performance. In this article, we'll delve into the world of mullite bricks, helping you make an informed procurement decision.

Mullite bricks are widely used in high - temperature industrial environments. They offer high refractoriness, good thermal shock resistance, and low thermal conductivity. These properties make them indispensable in industries such as metallurgy, glass, and ceramics. By using the right mullite bricks, you can improve the efficiency and longevity of your equipment, ultimately reducing your production costs.

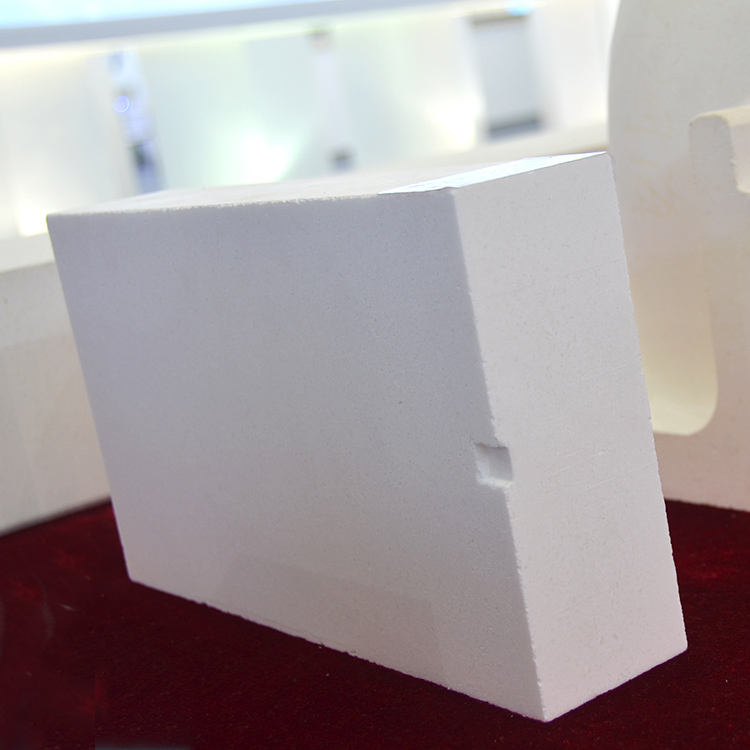

Sintered mullite bricks are made from natural bauxite, high - alumina clay, and other raw materials. These materials are first crushed and milled into fine powder. Then, they are mixed with binders and formed into bricks. After that, the bricks are sintered at high temperatures, usually around 1600 - 1800°C. The resulting bricks have a dense structure, high strength, and good chemical stability. They can withstand temperatures up to 1700°C and have a thermal conductivity of about 1.5 - 2.0 W/(m·K) at 1000°C.

Fused mullite bricks are produced by melting high - purity alumina and silica raw materials in an electric arc furnace at extremely high temperatures, around 2000 - 2200°C. The molten material is then poured into molds and cooled slowly. Fused mullite bricks have a more uniform crystal structure, higher purity, and better thermal shock resistance compared to sintered ones. They can resist temperatures up to 1800°C and have a lower thermal conductivity of about 1.0 - 1.5 W/(m·K) at 1000°C.

| Aspect | Sintered Mullite Bricks | Fused Mullite Bricks |

|---|---|---|

| Raw Materials | Natural bauxite, high - alumina clay | High - purity alumina and silica |

| Production Process | Crushing, mixing, forming, sintering | Melting, pouring, cooling |

| Temperature Resistance | Up to 1700°C | Up to 1800°C |

| Thermal Conductivity at 1000°C | 1.5 - 2.0 W/(m·K) | 1.0 - 1.5 W/(m·K) |

In the metallurgical industry, sintered mullite bricks are often used in blast furnaces, hot stoves, and steel ladles due to their high strength and chemical stability. Fused mullite bricks, on the other hand, are preferred in glass melting furnaces and ceramic kilns because of their excellent thermal shock resistance and low thermal conductivity. For example, a glass manufacturing company found that by using fused mullite bricks in their melting furnace, they were able to reduce energy consumption by 15% and increase the service life of the furnace by 20%.

In conclusion, both sintered and fused mullite bricks have their own unique characteristics and are suitable for different application scenarios. It's crucial for you to choose the right type of mullite bricks according to your specific needs. Our company offers a wide range of high - quality mullite bricks, including both sintered and fused types, which can fully meet your diverse requirements. Whether you need high - strength bricks for metallurgy or energy - efficient bricks for glass production, we have the perfect solution for you.

Contact us today to learn more about our mullite bricks and how they can benefit your business. Our experts are standing by to assist you in making the best procurement decision.