In the highly competitive glass manufacturing industry, businesses are constantly seeking ways to reduce costs and enhance production efficiency. One of the key challenges faced by glass manufacturers is the high cost associated with maintaining and replacing equipment due to wear and tear. This is where sillimanite nozzles and pipes come into play, offering a solution that can significantly extend the lifespan of glass production equipment and improve its stability.

The glass industry is under continuous cost pressure. According to industry reports, on average, glass manufacturers spend approximately 15 - 20% of their annual production budget on equipment maintenance and replacement. Traditional materials used in glass production equipment often have limited resistance to high - temperature and chemical corrosion, leading to frequent breakdowns and replacements. This not only increases costs but also disrupts production schedules, resulting in lost productivity.

Sillimanite nozzles and pipes possess excellent thermal shock stability. In glass production, equipment is exposed to rapid temperature changes. For example, when molten glass at around 1400 - 1500°C comes into contact with the equipment, traditional materials may crack due to thermal stress. However, sillimanite can withstand temperature differences of up to 1000°C without significant damage. This high thermal shock resistance reduces the likelihood of cracks and fractures, thereby extending the equipment's lifespan.

Another remarkable property of sillimanite products is their resistance to molten glass erosion. Molten glass is highly corrosive, and over time, it can wear away the inner surface of equipment. Sillimanite has a low reactivity with molten glass, which means it can maintain its integrity even after long - term contact with molten glass. Tests have shown that sillimanite nozzles can last 3 - 5 times longer than traditional ceramic nozzles in the same operating conditions.

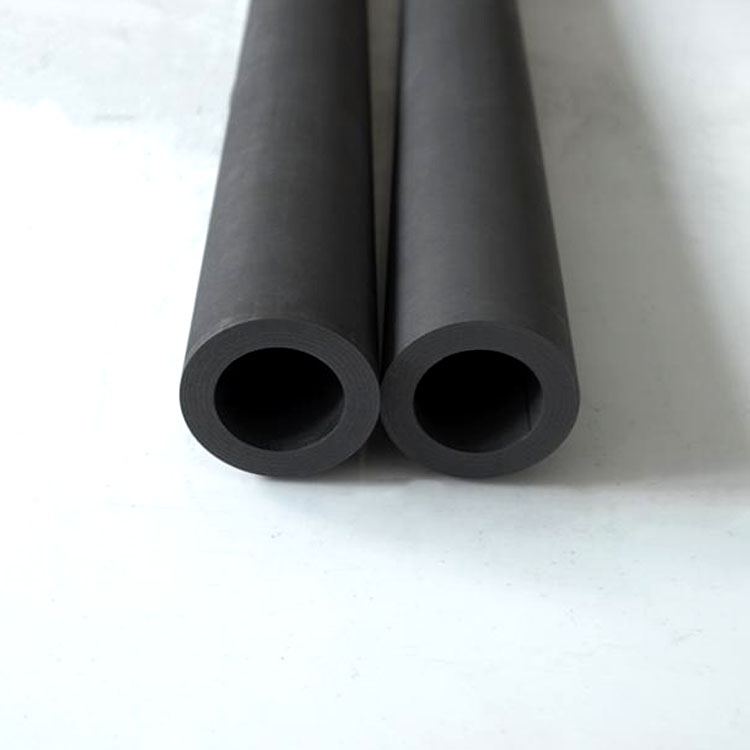

The main forms of sillimanite products used in glass production are nozzles and pipes. Nozzles are crucial in the glass feeding process, controlling the flow and shape of molten glass. Pipes are used to transport molten glass from one part of the production line to another. In glass feeding equipment, sillimanite nozzles ensure a smooth and consistent flow of molten glass, reducing the occurrence of blockages and improving the quality of the final glass products. In the tube - drawing mechanism, sillimanite pipes maintain the stability of the glass flow, resulting in more uniform glass tubes.

When comparing sillimanite products with traditional materials, the cost - benefit advantage of sillimanite is evident. A case study of a medium - sized glass manufacturer showed that after replacing traditional nozzles with sillimanite nozzles, the maintenance frequency decreased from once every 2 months to once every 6 - 8 months. This reduction in maintenance not only saved on labor and material costs but also increased the annual production time by approximately 10 - 15 days. In terms of overall cost savings, the manufacturer estimated a 20 - 25% reduction in equipment - related costs within the first year of using sillimanite products.

One of our customers, a well - known glass company in Europe, was facing high production costs due to frequent equipment failures. After switching to our sillimanite nozzles and pipes, they noticed a significant improvement in production efficiency. The equipment downtime was reduced by 30%, and the quality of their glass products also improved. This success story is a testament to the effectiveness of sillimanite products in real - world glass production scenarios.

.jpg)

If you are a glass manufacturer looking to reduce costs, improve production efficiency, and enhance the quality of your products, sillimanite nozzles and pipes are the ideal solution. Our products offer a proven way to extend the lifespan of your glass production equipment and increase its stability. Don't miss out on this opportunity to transform your glass production process.

Explore Sillimanite Products for Your Glass Production