In the highly demanding realm of industrial kilns and high-temperature furnaces, selecting the optimal refractory material is pivotal for operational efficiency and longevity. Among the myriad of options, mullite bricks have emerged as the preferred choice worldwide. This article delves into the intrinsic advantages of mullite bricks—primarily composed of the mineral mullite (3Al2O3·2SiO2)—and explains why they stand out in global refractory markets.

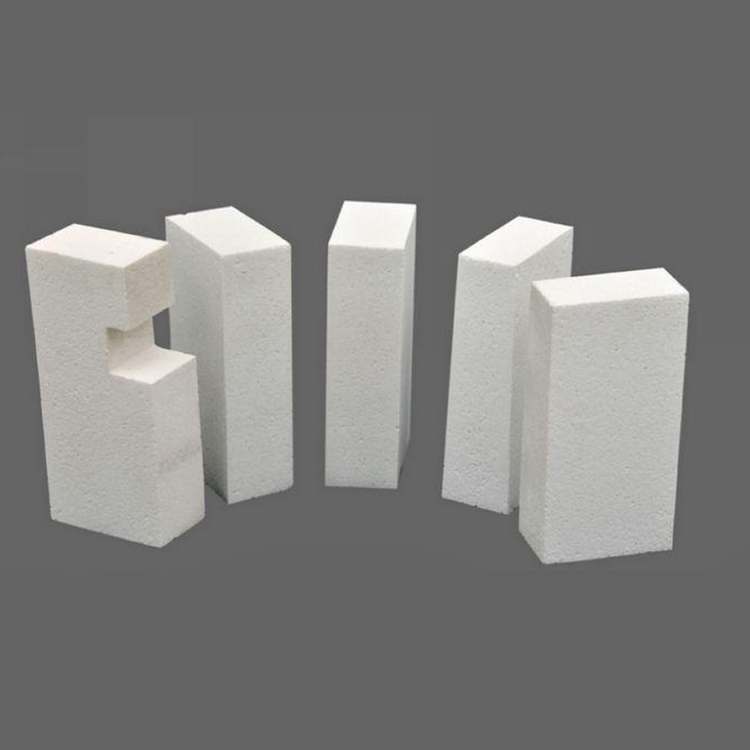

Mullite bricks belong to the high-alumina refractory category and boast superior thermal and chemical properties. Characterized by outstanding mechanical strength at elevated temperatures, they are engineered either through bauxite-based sintering (sintered mullite bricks) or intensive electric fusion (fused mullite bricks). These two types serve distinct industrial needs, but it is the sintered variant — manufactured from compounded raw materials, pressed under high pressure, and fired above 1600°C — that captures the attention of buyers for its balance of performance and cost-effectiveness.

The production process significantly influences the brick's final properties. Sintered mullite bricks start with a carefully formulated mix of alumina-rich raw materials. This mix undergoes high-pressure forming to achieve optimal density and geometry. The critical firing step at temperatures exceeding 1600°C triggers phase formation, solidifying mullite as the dominant crystalline phase. This high-temperature firing ensures:

Industry-standard ISO 12677 confirms that sintered high-alumina bricks maintaining firing temperatures above 1600°C demonstrate a minimum modulus of rupture of 40 MPa and thermal shock resistance over 20 cycles, underscoring their reliability under extreme conditions.

Numerous global kiln operators across steelmaking, ceramics, and glass industries have reported impressive outcomes after switching to sintered mullite bricks:

These factors position sintered mullite bricks as a strategic investment that not only enhances process performance but also drives meaningful cost reduction.

It is essential for procurement professionals and engineers to consider operational parameters—such as the maximum working temperature, atmosphere, and mechanical load—when choosing between fused and sintered mullite bricks. While fused mullite bricks offer higher purity and resistance suitable for ultra-high temperature or corrosive environments, sintered mullite bricks represent the optimal balance for most industrial furnaces requiring:

Understanding these distinctions helps buyers prioritize mullite bricks effectively, ensuring their material choices elevate production efficiency and lower long-term maintenance costs.

As industrial facilities globally strive to improve throughput while minimizing downtime and operational expenditures, mullite bricks—especially the sintered variety—stand out as a proven, high-performance refractory solution. Procurement specialists evaluating refractory options should consider not only upfront cost but also the lifecycle benefits such as enhanced durability, resistance to chemical attack, and lower energy losses.

What are your current refractory challenges? Could sintered mullite bricks boost your kiln efficiency and reduce maintenance cycles? Join the discussion or consult with experts to identify tailored solutions that perfectly fit your industrial furnace requirements.