High-Temperature Corundum Bricks for Ceramic Kilns: Application Insights and Technical Analysis

05 01,2026

Application Tutorial

Ceramic kilns frequently face challenges such as high-temperature damage and chemical corrosion, leading to shortened service life and inconsistent product quality. This article offers an in-depth analysis of the superior performance of high-temperature resistant corundum bricks in the ceramic industry. Featuring an ultra-high refractoriness above 1700°C, excellent wear resistance, and strong corrosion resistance, corundum bricks significantly extend kiln longevity and improve ceramic yield. Through real-world case studies and performance comparisons, this guide helps you quickly assess suitability for your production needs and provides tailored solutions to reduce costs and enhance efficiency, boosting your competitive edge.

Enhancing Ceramic Kiln Efficiency with High-Temperature Corundum Bricks: Experience and Technical Insight

Ceramic kiln operators worldwide face persistent challenges such as rapid high-temperature damage, chemical corrosion, and inconsistent product quality. These issues not only shorten kiln service life but also erode profitability. But what if you could significantly extend your kiln lifespan and boost your ceramic yield with one material upgrade?

This article delves into the outstanding application of high-temperature corundum bricks in ceramic kiln refractory linings — renowned for their ability to withstand temperatures above 1700°C, superb abrasion resistance, and excellent chemical stability.

Addressing Kiln Pain Points: Durable Performance When It Matters Most

Kilns firing at high temperatures face two primary threats:

- Severe thermal wear causing refractory bricks to crack or melt prematurely.

- Chemical corrosion from acidic and alkaline kiln slags that degrade materials.

These factors contribute to frequent maintenance interruptions, higher operational costs, and compromised ceramic product integrity. If you are struggling with low product yield or frequent downtime, the right refractory material could be your game changer.

Why Corundum Bricks? Core Properties That Transform Kiln Efficiency

Corundum bricks excel by combining three critical features:

- Exceptional abrasion resistance: Minimizes wear and tear from mechanical stress, ensuring structural integrity over extended cycles.

- Strong chemical durability: Resists corrosive attack from acidic or alkaline slags common in ceramic firing processes.

- Ultra-high refractoriness: Maintains stability above 1700°C, safeguarding kiln lining against thermal shocks and deformation.

These combined benefits make corundum bricks an ideal investment for enhancing kiln reliability and product consistency.

Data Snapshot: Switching from traditional high-alumina bricks to corundum bricks can increase kiln lining lifespan by approximately 30-50% and improve ceramic product yield by up to 15%.

Real-World Application: Case Studies of Corundum Brick Success

Across small, medium, and large ceramic manufacturers, corundum bricks have delivered measurable improvements:

- Medium-sized tile producer: Reduced kiln maintenance cycle from 8 to 12 months, cutting downtime by 25%.

- Large sanitary ware manufacturer: Achieved 10% enhancement in product uniformity by stabilizing kiln temperatures.

- Small artisanal ceramic workshop: Noticed clear resistance against kiln slag corrosion, preserving brick integrity over multiple firing batches.

Comparing Refractory Materials: Why Corundum Bricks Stand Out

| Property |

Clay Bricks |

High-Alumina Bricks |

Corundum Bricks |

| Max Service Temp (°C) |

~1400 |

~1600 |

>1700 |

| Abrasion Resistance |

Low |

Medium |

High |

| Chemical Corrosion Resistance |

Poor |

Fair |

Excellent |

| Maintenance Frequency |

High (3-6 months) |

Moderate (6-9 months) |

Low (12-18 months) |

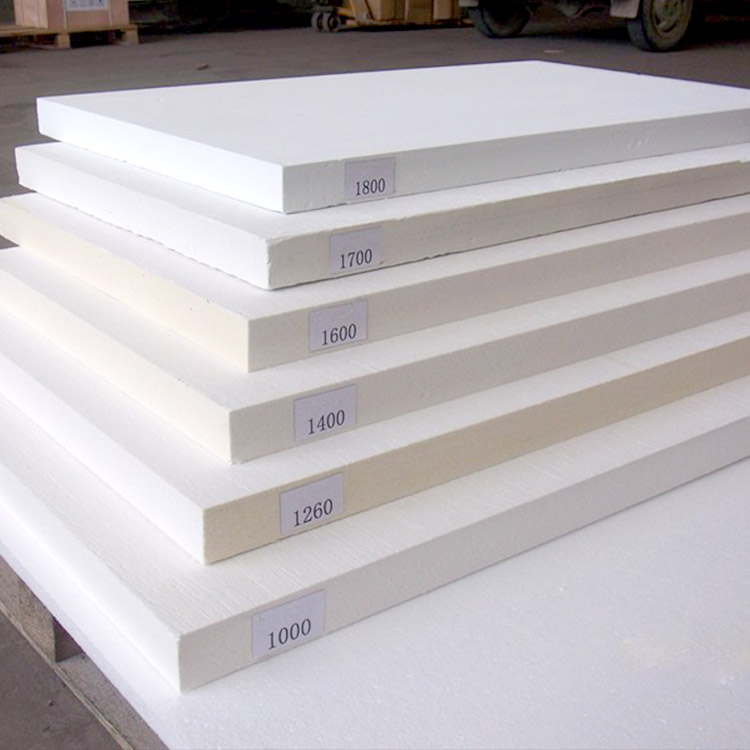

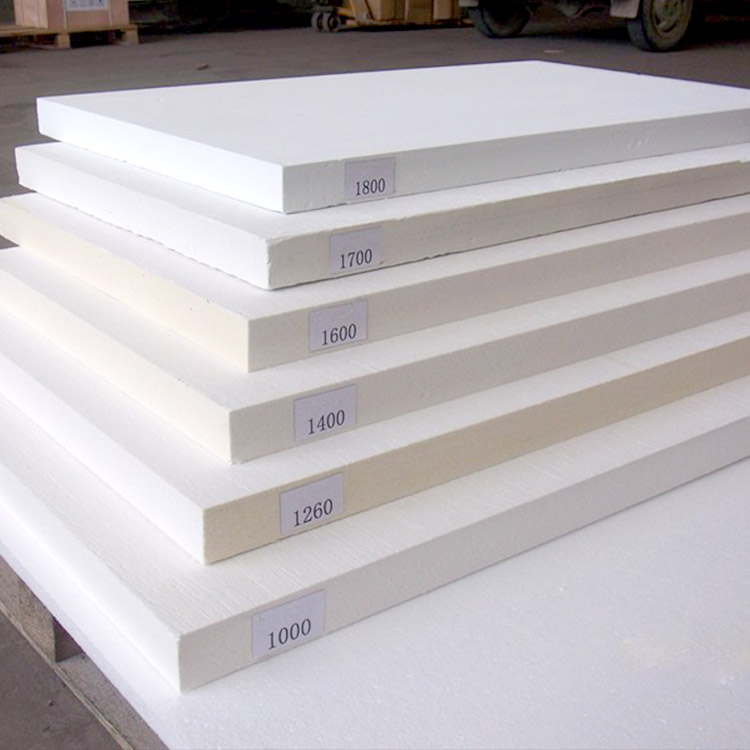

Tailored Selection Guidance: Matching Corundum Brick Types to Your Kiln Needs

Not all corundum bricks are created equal. To achieve optimal results, consider:

- Production scale: High-volume operations benefit from durable electric-fused corundum bricks, while smaller setups may choose sintered types for cost efficiency.

- Operating temperature: Ensure the brick’s refractoriness rating exceeds peak kiln temperatures by at least 200°C for safety margin.

- Firing process specifics: Acidic kiln slags require higher corrosion resistance; alkaline environments call for bricks with optimized chemical stability.

With the right selection, corundum bricks are not just refractory materials—they are your kiln’s shield against inefficiencies and unexpected downtime.

Making the Decision: Unlock Long-Term Value Beyond Initial Investment

While corundum bricks may require a higher upfront cost compared to traditional options, the return on investment through reduced maintenance, fewer production interruptions, and elevated product quality is compelling.

As one ceramic plant manager put it, “Upgrading to corundum bricks was transformational — our kiln runs smoother, and the consistency of our tiles has never been better. It’s not just about enduring the heat, it’s about increasing every batch’s value.”