When it comes to selecting refractory materials for ceramic kilns, your ultimate goal is clear: make your kiln more durable, your products more consistent, and your profits higher. Yet, harsh high-temperature environments, chemical corrosion from molten slag, and wear can drastically reduce the lifespan of refractory linings—leading to higher maintenance costs and unstable ceramic quality.

Enter high-temperature corundum bricks. These advanced refractory materials offer exceptional performance tailored for ceramic production, resolving many pain points faced by kiln operators worldwide. Below, we’ll dive into their four key advantages and why they are the ideal choice for your ceramic kiln's demanding environment.

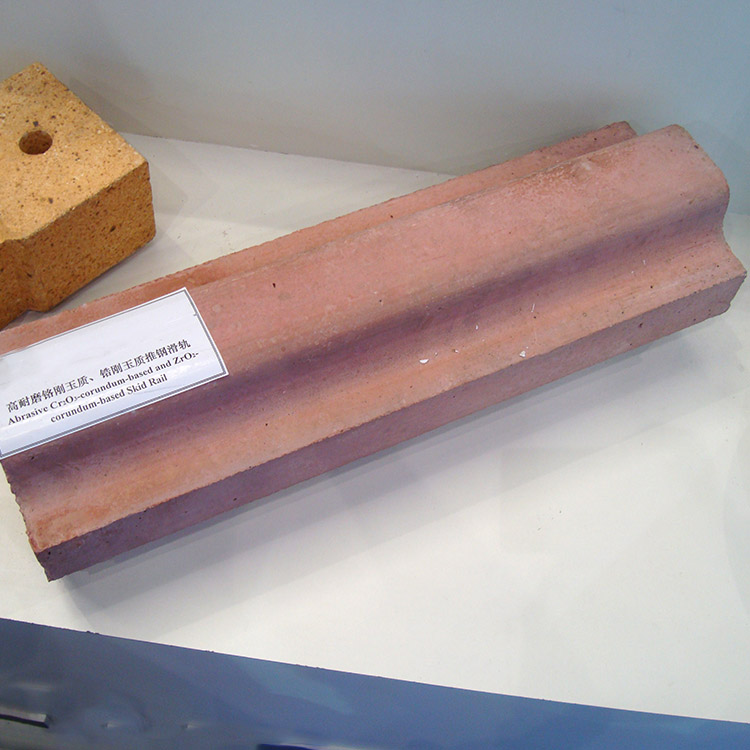

Corundum bricks exhibit excellent wear resistance that significantly decreases mechanical abrasion inside your kiln. This feature is critical since constant movement of raw materials and thermal cycling causes considerable wear on refractory linings.

Studies show that using corundum bricks can reduce abrasive wear by up to 40-50% compared to traditional fireclay or silica bricks.

"Switching to corundum bricks extended our kiln's service life by nearly 30%, reducing downtime and repair costs significantly." – Ceramic Plant Manager, Guangdong, China

Highly resistant to chemical attack, corundum bricks withstand corrosive slag erosion better than alumina or magnesia bricks. This is essential for ceramic kilns dealing with flux-rich materials where slag buildup corrodes lining materials prematurely.

This strong anti-corrosion capability protects your kiln’s integrity and ensures consistent thermal performance throughout production cycles.

Corundum bricks maintain structural stability at ultra-high temperatures exceeding 1700°C, making them suitable for advanced ceramic sintering processes that demand extreme heat endurance.

This superior heat resistance mitigates thermal shock damage and preserves kiln shape, assuring consistent firing conditions and product uniformity.

The chemical purity and stability of corundum bricks prevent unwanted reactions that would contaminate ceramic products during firing.

This guarantees your final ceramics maintain their intended color, strength, and composition — a vital factor for high-end and technical ceramics.

Across multiple ceramic production lines, corundum bricks have demonstrated remarkable operational improvements:

| Material | Service Life | Maintenance Cost | Heat Resistance | Corrosion Resistance |

|---|---|---|---|---|

| Corundum Brick | High (~30% longer) | Low | >1700°C | Excellent |

| Fireclay Brick | Moderate | Medium | ~1400°C | Moderate |

| Silica Brick | Low | High | ~1600°C | Poor |

Your ceramic production scale and firing process determine the best off-the-shelf or tailored corundum brick solution:

Consult with refractory experts to identify the right product mix that optimizes your kiln’s efficiency and lifespan.

Discover how high-temperature corundum bricks can elevate your production efficiency and product quality—customized to your kiln’s needs.

Get Your Expert Corundum Brick Solution Today