As a decision-maker in the ceramic industry, you're well aware of the constant challenges posed by ceramic kilns. Operating at high temperatures for extended periods, these kilns often face issues such as refractory material wear, chemical erosion, and fluctuations in product quality. These problems not only shorten the kiln's lifespan but also lead to lower production yields and inconsistent product quality. But what if there was a solution that could address all these concerns?

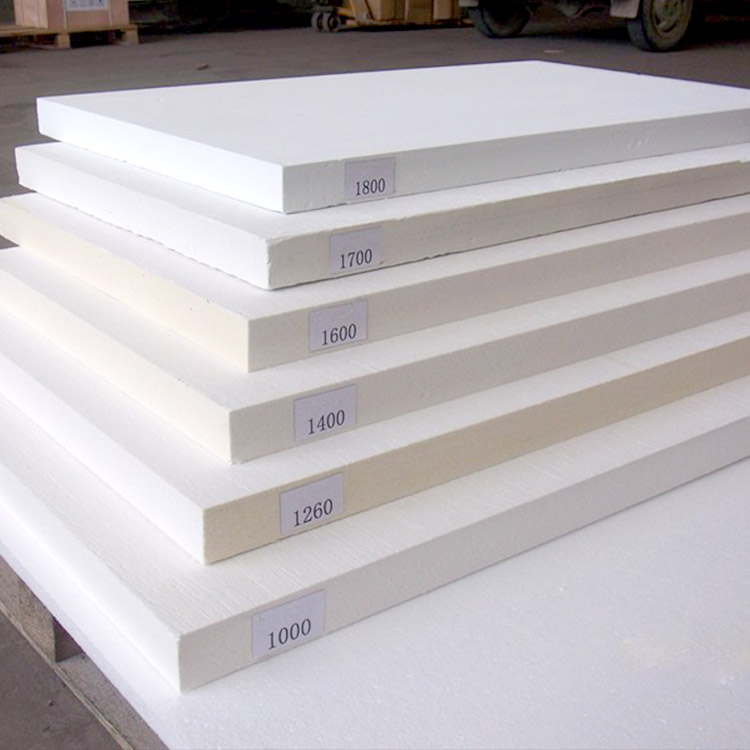

High-temperature refractory corundum bricks are the answer you've been looking for. These bricks are designed with several core features that make them ideal for ceramic kilns:

Don't just take our word for it. Let's look at some real-world examples of how corundum bricks have transformed ceramic production. A medium-sized ceramic factory switched to corundum bricks and saw a 40% increase in kiln lifespan. Another large-scale factory reported a 30% improvement in product yield and a significant reduction in product defects.

When it comes to choosing refractory materials for your kiln, it's essential to compare different options. Let's take a look at how corundum bricks stack up against common alternatives like clay bricks and mullite bricks:

| Material | Abrasion Resistance | Corrosion Resistance | Refractoriness | Cost |

|---|---|---|---|---|

| Corundum Bricks | High | Excellent | Above 1700°C | Moderate (long-term cost-effective) |

| Clay Bricks | Low | Poor | Around 1300 - 1500°C | Low (but higher long-term cost) |

| Mullite Bricks | Medium | Good | Around 1500 - 1600°C | Medium |

As you can see, while clay bricks may have a lower upfront cost, their poor performance means you'll likely need to replace them more frequently, leading to higher long-term costs. Corundum bricks, on the other hand, offer a better balance of performance and cost.

We understand that every ceramic business is unique, with different production scales and technological requirements. That's why we offer customized solutions. Whether you're a small workshop or a large industrial plant, we can recommend the most suitable type and configuration of corundum bricks for your specific needs. Our experts will work closely with you to analyze your production process and provide tailored advice to ensure you get the maximum benefit from our products.

Investing in high-temperature refractory corundum bricks is not just about solving immediate problems; it's about securing your business's long-term success. By improving kiln lifespan, increasing production yields, and enhancing product quality, these bricks can significantly boost your bottom line. They also give you a competitive edge in the market, allowing you to produce higher-quality products more efficiently.

Let your kiln be more durable and your products more stable—start with a corundum brick. Contact us now to learn more about how corundum bricks can transform your ceramic production!