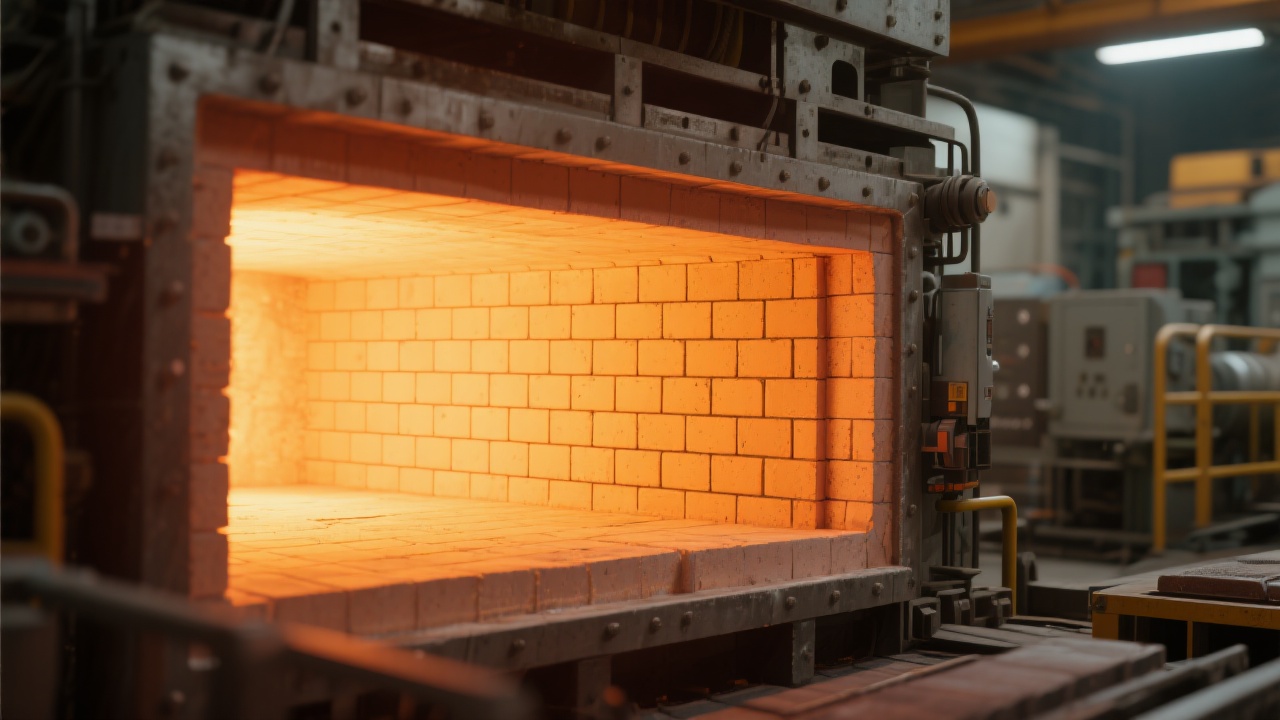

In the steel industry, furnace lining durability directly impacts production uptime and cost efficiency. That’s where high-alumina firebrick—specifically those with over 90% Al₂O₃ content—comes in. This isn’t just another refractory material; it’s a proven solution for extending furnace life while boosting throughput.

| Property | Typical Value | Why It Matters |

|---|---|---|

| Al₂O₃ Content | >90% | Resists chemical attack from molten slag at 1600°C+ |

| Cold Crushing Strength | ≥120 MPa | Withstands mechanical stress during installation & operation |

| Wear Resistance | >95% retention after 1000 hrs @ 1500°C | Reduces replacement frequency by up to 40% |

These properties aren’t theoretical—they’ve been validated through real-world testing. For example, a European steel mill reported a 37% reduction in furnace downtime after switching from traditional clay bricks to high-alumina firebrick (per ISO 18898-2021).

Take the case of a mid-sized steel plant in India that was struggling with frequent refractory failure due to aggressive iron oxide slags. After installing electric-fused alumina brick (95% Al₂O₃), their average furnace campaign length increased from 6 months to 11 months—a 83% improvement in service life.

In glass manufacturing, similar gains were seen. A U.S.-based container glass producer replaced their conventional magnesia-chrome brick with sintered alumina brick. The result? Lower energy consumption (+5% thermal efficiency) and reduced maintenance costs (estimated savings: $18K/month).

Both types offer excellent performance, but they serve different needs:

The choice depends on your process conditions—not just price. In one instance, a German steel company initially chose sintered brick for its lower upfront cost—but after three months of accelerated erosion, switched to fused alumina, cutting repair costs by 60% annually.

If you're facing issues like rapid furnace lining wear or inconsistent product quality, it's time to evaluate whether your current refractory system can keep up with modern demands.

High-alumina firebrick isn't just durable—it’s smart investment. With data-backed performance, proven ROI, and minimal disruption during installation, it’s the ideal upgrade path for any steel or glass producer looking to reduce waste, increase output, and build long-term resilience.

What’s your biggest challenge with furnace lining today? Is it erosion? Thermal cycling? Or something else? Let us know your scenario—we’ll send you 3 tailored solutions used successfully by companies like yours.

Get Your Free Refractory Optimization Guide Now