In various industrial production processes, especially those involving high - temperature environments such as steelmaking, glass manufacturing, and cement production, the demand for high - quality refractory materials is extremely high. Ordinary refractory materials often face problems such as rapid wear, cracking, and reduced insulation performance under high - temperature conditions, which can lead to frequent replacements, increased production costs, and potential safety hazards.

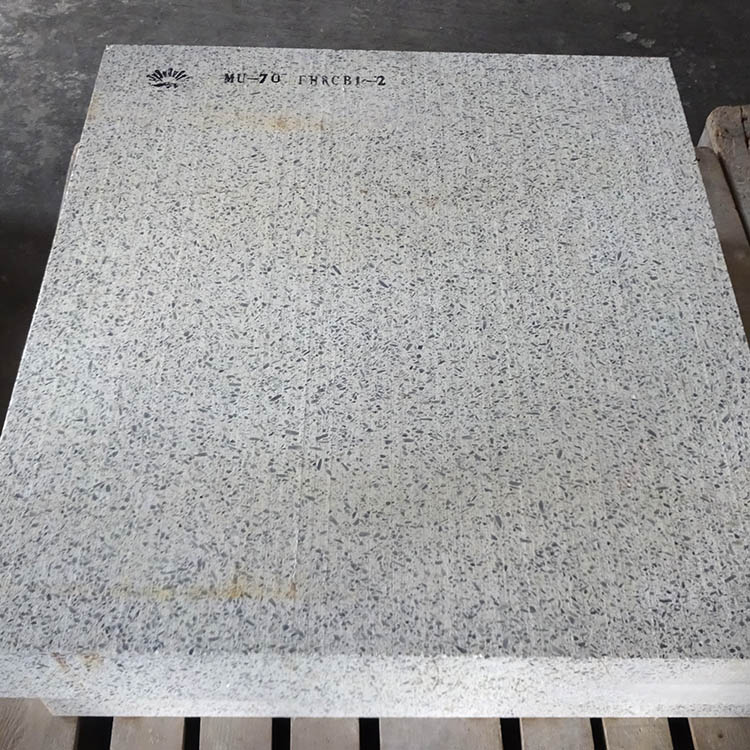

Sintered mullite bricks are high - performance refractory materials with mullite as the main crystalline phase. They are made from synthetic mullite clinker and high - alumina bauxite clinker and fired at a high temperature of over 1600°C. These bricks have a stable structure and excellent refractory performance, making them an ideal choice for high - temperature industrial applications.

Synthetic mullite clinker has a high purity, typically with an alumina content of over 70%. It has a uniform crystal structure, which endows the sintered mullite bricks with good thermal shock resistance. Tests have shown that under cyclic thermal shock conditions, bricks made with synthetic mullite clinker can withstand more than 50 cycles without significant damage, while ordinary bricks may start to crack after only 10 - 15 cycles.

High - alumina bauxite clinker is rich in alumina, usually with an alumina content of 60% - 85%. It provides high strength and hardness to the sintered mullite bricks. In compression tests, bricks containing high - alumina bauxite clinker can withstand a pressure of up to 300 MPa, which is much higher than the 150 - 200 MPa of some common refractory bricks.

The high - temperature firing process at over 1600°C is crucial for the performance of sintered mullite bricks. At this temperature, the synthetic mullite clinker and high - alumina bauxite clinker undergo a series of physical and chemical reactions, forming a dense and stable structure.

| Firing Temperature | Compressive Strength (MPa) | Thermal Shock Resistance (Cycles) |

|---|---|---|

| 1500°C | 200 | 20 - 30 |

| 1600°C | 300 | 50+ |

In steelmaking furnaces, sintered mullite bricks are used in the lining of the furnace walls. They can withstand the high temperatures of up to 1700°C in the steelmaking process and resist the corrosion of molten steel and slag. For example, in a large - scale steel plant, using sintered mullite bricks has extended the service life of the furnace lining from 1 - 2 years to 3 - 5 years, significantly reducing maintenance costs.

In glass melting furnaces, these bricks are used in the areas in contact with the molten glass. They have good chemical stability and can prevent the contamination of the glass. A glass factory reported that after using sintered mullite bricks, the quality of the glass products has been improved, and the defect rate has been reduced from 5% to 2%.

If you are looking for high - quality refractory materials that can withstand extreme high - temperature environments and provide long - term stability, our sintered mullite bricks are the perfect solution. We invite you to learn more about our products. You can contact our professional sales team for detailed product information or request a free sample to test the performance of our sintered mullite bricks in your specific application. Don't miss this opportunity to upgrade your industrial refractory solutions!

Contact us now at [Contact Email] or [Contact Phone] to get more information and request a free sample!