High-temperature industrial processes are essential in sectors like steelmaking, glass manufacturing, and ceramics. However, the durability of traditional refractory materials often falls short under extreme conditions, leading to frequent replacements and increased operational costs. In this context, sintered mullite bricks have emerged as a reliable solution for industries seeking long-term performance and cost efficiency.

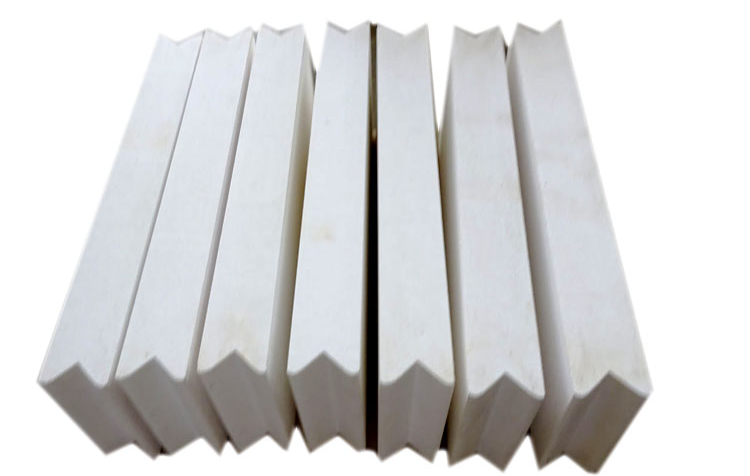

Sintered mullite bricks are high-alumina refractory products primarily composed of mullite, a mineral known for its exceptional thermal stability and resistance to high temperatures. These bricks are manufactured using synthetic mullite clinker and high-alumina bauxite clinker, which are fired at temperatures exceeding 1600°C. This process ensures a dense, stable structure that can withstand prolonged exposure to intense heat without degrading.

The quality of sintered mullite bricks is heavily influenced by the raw materials used. Synthetic mullite clinker provides a uniform composition and enhanced structural integrity, while high-alumina bauxite clinker contributes to superior thermal shock resistance. Together, these materials ensure that the final product maintains its shape and strength even in the most demanding environments.

The firing process plays a critical role in determining the performance of sintered mullite bricks. When fired at temperatures above 1600°C, the material undergoes complete sintering, resulting in minimal porosity and maximum density. Compared to bricks fired at lower temperatures, those produced at higher temperatures demonstrate significantly better resistance to thermal stress and chemical erosion.

| Firing Temperature | Porosity (%) | Cold Crushing Strength (MPa) |

|---|---|---|

| 1400°C | 12.5 | 55 |

| 1600°C | 6.2 | 90 |

Sintered mullite bricks have been successfully applied across multiple industries. For example, in the steel industry, they are used in blast furnace linings and ladle covers, where they resist thermal cycling and molten slag. In glass manufacturing, they serve as insulation materials in melting tanks, maintaining consistent temperatures and reducing energy consumption. Similarly, in ceramic production, these bricks are ideal for kiln walls due to their excellent thermal conductivity and dimensional stability.

With their combination of high-temperature resistance, mechanical strength, and long service life, sintered mullite bricks offer a sustainable and cost-effective alternative to conventional refractories. Whether you're operating in steel, glass, or ceramic production, these bricks provide the reliability needed to maintain efficient operations and reduce downtime.

If you are looking for a durable and high-performance refractory solution, we invite you to learn more about our sintered mullite brick products. Our team is ready to provide detailed technical data, application support, and customized solutions tailored to your specific needs.