In the industrial landscape, corrosion of equipment such as glass furnaces and blast furnace linings is a persistent problem. It not only leads to significant efficiency losses but also drives up maintenance costs. For instance, in some glass manufacturing plants, equipment corrosion can cause a production efficiency decline of up to 20%, and maintenance costs can account for as much as 15% of the total production cost annually.

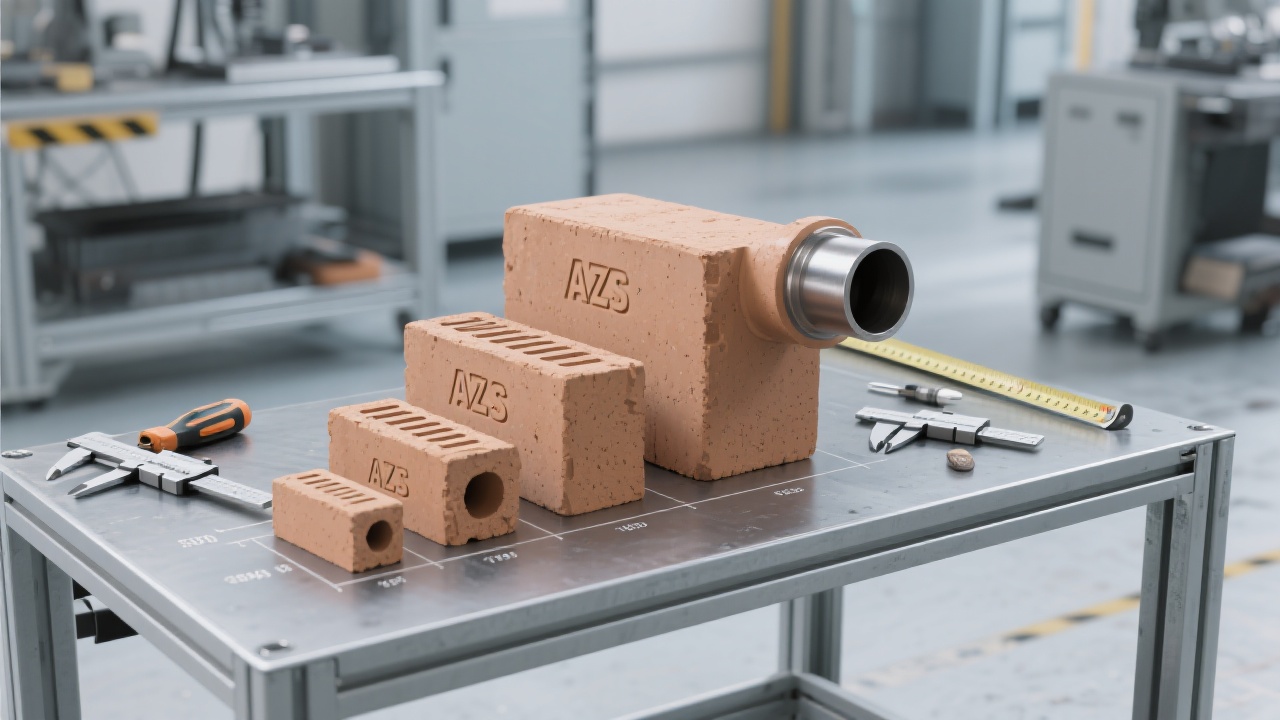

Sillimanite bricks are crafted through a meticulous manufacturing process. They are primarily made from high - quality sillimanite raw materials, which are rich in aluminum silicate. During the production, the raw materials are first crushed and ground to a specific particle size. Then, they are mixed with appropriate binders and additives. After shaping under high pressure, the bricks are fired at high temperatures, usually around 1400 - 1500°C. This process endows the bricks with excellent physical and chemical properties.

One of the most prominent features of sillimanite bricks is their high refractoriness. They can withstand temperatures up to 1750°C without significant deformation, which is crucial for high - temperature industrial environments like glass furnaces and blast furnaces. In a glass furnace, where the operating temperature often exceeds 1500°C, the high refractoriness of sillimanite bricks ensures the long - term stability of the furnace lining.

Another important characteristic is their good thermal shock stability. In industrial processes, equipment often experiences rapid temperature changes. Sillimanite bricks can resist the damage caused by thermal shock, reducing the risk of cracking and spalling. Tests have shown that sillimanite bricks can withstand more than 50 thermal shock cycles from room temperature to 1100°C without obvious damage.

In terms of corrosion resistance, sillimanite bricks are highly effective against various corrosive substances, such as molten glass, slag, and gases. In a blast furnace, the lining made of sillimanite bricks can effectively resist the erosion of slag, which extends the service life of the furnace lining.

In glass furnaces, the use of corrosion - resistant sillimanite bricks can significantly improve production efficiency. The high refractoriness and corrosion resistance of these bricks reduce the frequency of furnace repairs and replacements. As a result, the downtime of the glass furnace is reduced, and continuous production can be ensured. Some glass manufacturers have reported that after using sillimanite bricks, the production efficiency has increased by about 15%.

Similarly, in blast furnaces, the excellent performance of sillimanite bricks helps to maintain a stable operating environment. The long - lasting lining reduces the interference of lining damage on the smelting process, improving the quality and quantity of iron production. In some iron and steel enterprises, the use of sillimanite bricks in blast furnace linings has led to a 10% increase in iron output.

A well - known glass manufacturing company in Europe was facing severe corrosion problems in its glass furnaces. The original furnace lining materials had a short service life, and frequent repairs affected production. After replacing the lining with corrosion - resistant sillimanite bricks, the service life of the furnace lining was extended from 1.5 years to 3 years. At the same time, the production efficiency increased by 18%, and the maintenance cost was reduced by 30%.

In an iron and steel plant in Asia, the blast furnace lining was suffering from rapid erosion by slag. After adopting sillimanite bricks, the erosion rate of the lining was significantly reduced. The blast furnace could operate stably for a longer time, and the iron production increased by 12% within a year.

Choosing corrosion - resistant sillimanite bricks for glass furnace and blast furnace linings can bring multiple benefits to enterprises. It not only improves production efficiency and product quality but also reduces maintenance costs and downtime. These advantages translate into enhanced enterprise competitiveness in the market. By ensuring continuous and efficient production, enterprises can better meet market demand and gain a larger market share.

If you are looking for a reliable solution to improve the performance of your industrial equipment, click here to learn more about our corrosion - resistant sillimanite bricks and how they can transform your production process.