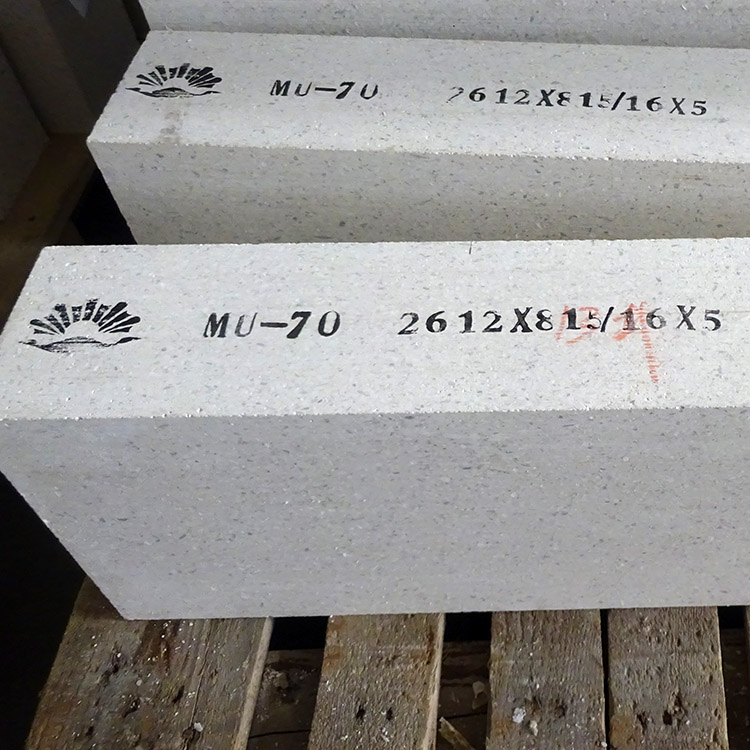

The manufacture of large cast mullite bricks, an essential refractory material for complex industrial applications, hinges on precision and advanced craftsmanship. This article delves into the entire production workflow, from initial raw material blending to the final high-temperature firing stage, highlighting the technical controls and quality assurance designed to meet the stringent demands of custom-shaped refractory components.

The process initiates with meticulous raw material mixing, where high-purity alumina and silica sources are proportioned to achieve the desired mullite phase. Precise slurry preparation ensures consistent rheology critical for castability. Subsequently, the slurry is manually poured into custom-designed gypsum molds, tailored for complex geometries that standard pressing cannot accommodate.

Once molded, the bricks undergo a controlled drying phase to remove excess moisture, preventing cracks and deformation. The final step involves firing in kilns at temperatures exceeding 1750°C, enabling the mullite crystals to form a dense structure that confers outstanding thermal stability and mechanical strength.

| Process Stage | Key Technical Points | Quality Control Focus |

|---|---|---|

| Raw Material Mixing | Particle size, slurry viscosity | Chemical composition analysis |

| Casting into Gypsum Molds | Mold precision, pour rate | Dimensional accuracy |

| Drying & Setting | Humidity & temperature control | Moisture content uniformity |

| High-Temperature Firing | Ramp rate, peak temperature precision | Mechanical strength and porosity |

Large cast mullite bricks excel in fulfilling the needs of irregular shapes, making them ideal for demanding environments such as:

“Our ability to supply complex-shaped mullite bricks on time has improved furnace uptime and reduced maintenance costs,” says an expert from a leading steel manufacturer.

Comparative studies demonstrate that large cast mullite bricks outperform traditional pressed bricks in three critical aspects:

| Criteria | Pressed Bricks | Large Cast Bricks | Improvement |

|---|---|---|---|

| Forming Precision | ±1.5mm | ±0.5mm | 66% reduction in tolerance |

| Waste Rate | 8-10% | 2-3% | 70% less waste |

| Production Efficiency | 15 days/cycle | 10 days/cycle | 33% faster turnaround |

Traditional refractory materials often struggle with fabricating intricate shapes without cracking or warping. Large cast mullite bricks alleviate these issues through improved slurry formulation and controlled thermal treatments, which minimize internal stresses.

This innovation has been well received by clients who previously faced frequent product failures, as reflected in their feedback:

"Since switching to large cast mullite bricks, our production disruptions due to refractory failures have dropped by over 40%. The tailored fit also enhances furnace performance significantly." – Quality Manager, Major Steel Plant

Rigorous laboratory tests confirm that the fired large cast mullite bricks exhibit flexural strength above 25 MPa and bulk density exceeding 2.8 g/cm³, benchmarks superior to typical pressed refractory bricks. Furthermore, preliminary thermal shock resistance tests show a 30% increase in cycles before failure, underscoring their reliability in extreme environments.

In a recent project, a leading steel plant commissioned large cast mullite bricks to replace their aged furnace lining components. The custom design involved over 100 uniquely shaped bricks, each dimensionally complex but produced within strict tolerance limits.

From initial digital design collaboration to the final kiln firing, the production cycle spanned less than two weeks — notably faster than previous suppliers. Post-installation, the plant reported smoother furnace operation and extended maintenance intervals, validating the efficacy of this tailored casting technology.

Is your refractory design challenged by complex shapes or tight tolerance demands? Discover how switching to large cast mullite bricks can transform your production quality while reducing lead times.