In the global industrial landscape, refractory materials play a pivotal role in high - temperature processes. However, many conventional refractory materials face challenges such as poor thermal stability, low corrosion resistance, and short service life. These issues can lead to frequent replacements, increased production costs, and even production interruptions. This is where sintered mullite bricks step in as a reliable solution.

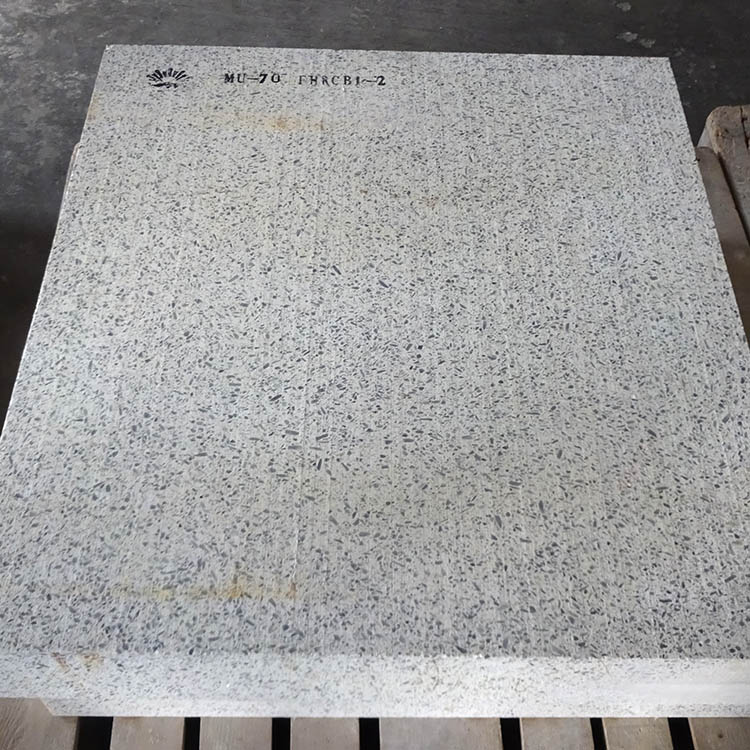

Sintered mullite bricks are a type of high - performance refractory material known for their excellent thermal and mechanical properties. They are made from carefully selected raw materials and undergo a series of strict manufacturing processes. The main chemical composition of sintered mullite bricks includes aluminum oxide (Al₂O₃) and silicon dioxide (SiO₂), typically with an Al₂O₃ content ranging from 60% to 80%, which gives them strong heat resistance and chemical stability.

The raw materials for sintered mullite bricks, synthetic mullite clinker and high - alumina bauxite clinker, bring significant advantages. Synthetic mullite clinker has a uniform crystal structure, high purity, and good thermal shock resistance. It can effectively enhance the overall performance of the bricks. High - alumina bauxite clinker, on the other hand, is rich in aluminum oxide, which provides the bricks with high refractoriness. For example, high - alumina bauxite clinker with an Al₂O₃ content of over 75% can ensure that the bricks maintain stable performance at high temperatures up to 1700°C.

The high - temperature firing process is a crucial step in the production of sintered mullite bricks. During this process, the raw materials are fired at temperatures between 1600°C and 1800°C. This high - temperature treatment helps to form a dense and stable crystal structure within the bricks, improving their strength, density, and thermal stability. For instance, bricks fired at 1750°C can achieve a compressive strength of over 100 MPa, which is much higher than that of common refractory materials.

In the steel industry, sintered mullite bricks have been widely used. For example, in blast furnaces, they are used in the hot air ducts and hearths. Their high thermal stability and corrosion resistance can effectively extend the service life of these parts. A steel plant in Europe reported that after using sintered mullite bricks in the hot air ducts, the replacement cycle was extended from 2 years to 5 years, reducing maintenance costs by 30%. In addition to the steel industry, sintered mullite bricks are also used in the glass industry, ceramic industry, and non - ferrous metal smelting industry. In the glass industry, they are used in the melting furnaces, where they can withstand the high - temperature and corrosive environment, improving the quality and production efficiency of glass products.

If you are in the consideration stage of sourcing high - performance refractory materials, sintered mullite bricks are definitely worth exploring. Their excellent performance, proven by numerous application cases, can bring long - term benefits to your production. To learn more about our sintered mullite bricks, including technical specifications, application solutions, and to request product samples, please contact us at [Contact Information]. We are committed to providing you with professional advice and high - quality products.

Ready to enhance your production efficiency with sintered mullite bricks? Contact us now for more information or to request a free sample!