Sintered mullite bricks are essential components in high-temperature industrial applications, offering exceptional thermal stability, mechanical strength, and chemical resistance. As global manufacturers face increasing demands for durable and efficient refractory materials, the choice of raw materials and production processes becomes crucial. This article explores the relationship between raw material selection and performance in sintered mullite bricks, providing insights that help industrial buyers make informed decisions.

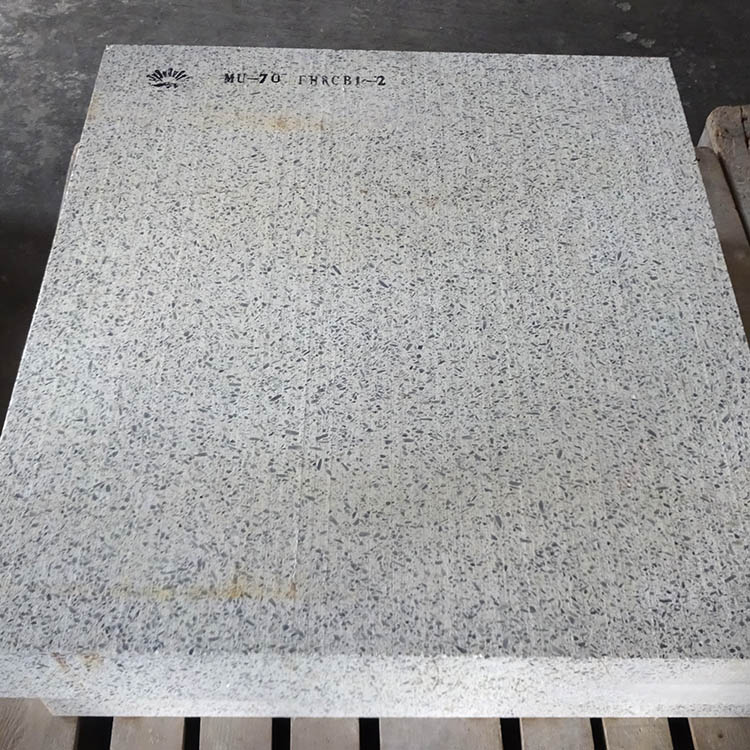

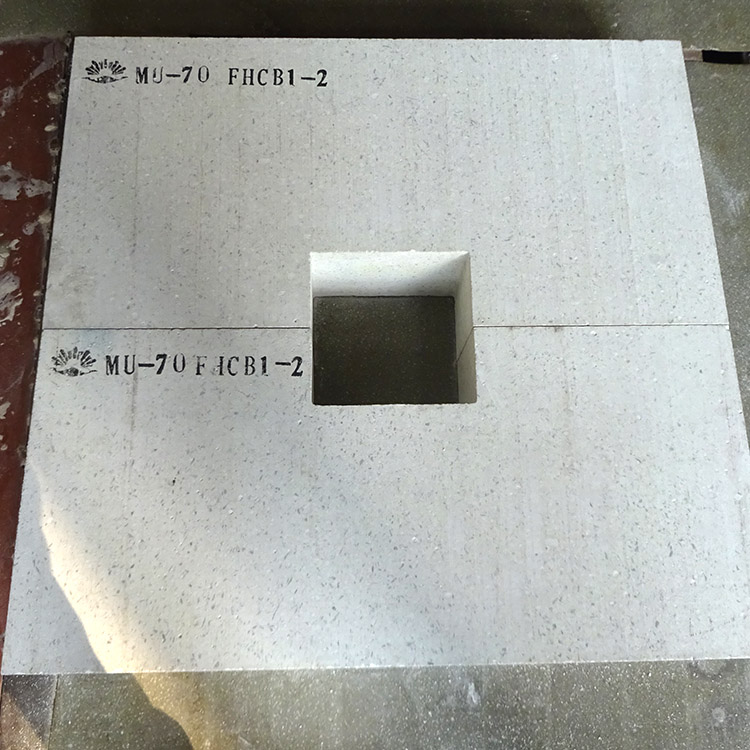

The performance of sintered mullite bricks largely depends on the quality of their raw materials. Two primary components are used: synthetic mullite clinker and high-alumina bauxite clinker. These materials are carefully selected to ensure optimal properties such as low porosity, high density, and excellent thermal shock resistance.

According to industry data, synthetic mullite clinker typically contains over 90% mullite (3Al₂O₃·2SiO₂), which provides superior structural integrity at elevated temperatures. High-alumina bauxite clinker, with an Al₂O₃ content exceeding 75%, enhances the brick’s resistance to slag and chemical erosion.

| Raw Material | Key Properties | Typical Use Cases |

|---|---|---|

| Synthetic Mullite Clinker | High thermal stability, low expansion | Cement kilns, glass furnaces |

| High-Alumina Bauxite Clinker | Excellent corrosion resistance | Steelmaking, petrochemical industries |

A critical step in producing high-quality sintered mullite bricks is the firing process, which typically occurs at temperatures above 1600°C. This ensures complete densification and phase transformation, resulting in a stable microstructure that can withstand extreme conditions.

Studies show that bricks fired at 1650°C exhibit up to 30% higher compressive strength compared to those fired at lower temperatures. Additionally, the high firing temperature minimizes residual porosity, improving the brick's resistance to thermal shock and mechanical wear.

Sintered mullite bricks have been widely adopted in various industrial sectors due to their reliable performance. For example, in cement plants, these bricks maintain structural integrity under prolonged exposure to high heat, reducing maintenance costs and downtime. In the steel industry, they resist molten slag and thermal stress, ensuring consistent furnace operation.

One leading manufacturer in Southeast Asia reported a 25% increase in furnace efficiency after replacing traditional refractories with sintered mullite bricks. Such success stories highlight the value of choosing the right materials for demanding environments.

Explore the advantages of sintered mullite bricks and discover how they can enhance your production efficiency and reduce long-term costs. Our team of experts is here to provide tailored solutions and technical support.

Contact Us Today