In the glass industry and other high - temperature industrial sectors, the demand for reliable refractory materials is crucial. Traditional refractory materials often face challenges such as poor thermal stability, short service life, and high maintenance costs. These issues can lead to production interruptions, increased energy consumption, and higher overall costs for manufacturers.

Sintered mullite bricks emerge as an excellent solution to these problems. Let's take a closer look at what makes them stand out.

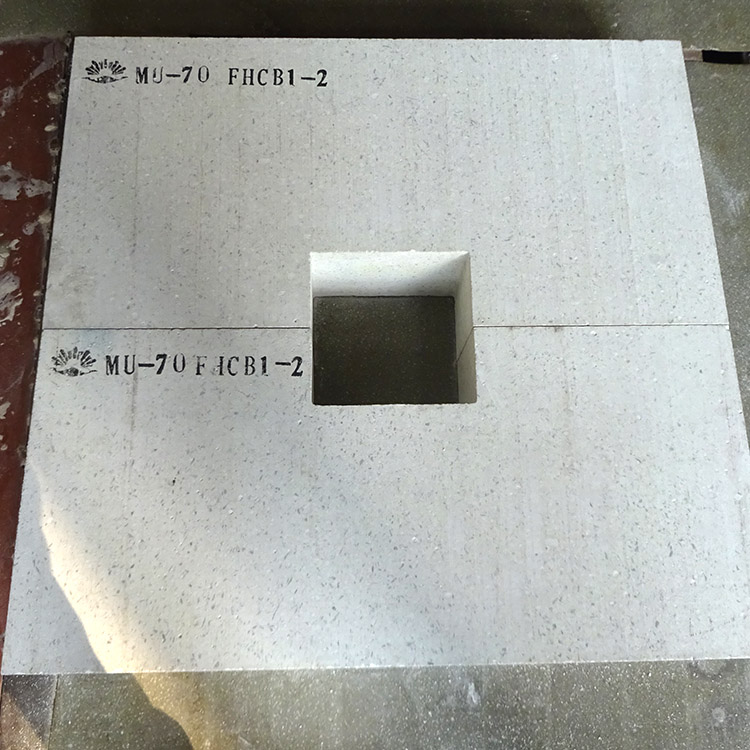

Sintered mullite bricks are high - performance refractory products known for their outstanding thermal and mechanical properties. They are made from carefully selected raw materials and undergo a strict manufacturing process.

The main raw materials for sintered mullite bricks are synthetic mullite clinker and high - alumina bauxite clinker. Synthetic mullite clinker offers a high alumina content, typically around 70 - 80%. This high alumina content contributes to the brick's excellent refractoriness, with a refractoriness under load (RUL) of up to 1600 - 1700°C. High - alumina bauxite clinker further enhances the brick's strength and wear resistance. Its natural crystal structure provides a stable framework, enabling the bricks to withstand high - intensity mechanical stress during operation.

One of the key steps in the production of sintered mullite bricks is high - temperature firing. These bricks are fired at temperatures between 1650 - 1750°C. This high - temperature firing process is of great significance:

Sintered mullite bricks have a wide range of applications in different industrial sectors:

In the glass industry, sintered mullite bricks are used in glass melting furnaces. They can withstand the high - temperature environment of up to 1500 - 1600°C during the glass melting process. A glass manufacturing company in Europe reported that after replacing traditional refractory bricks with sintered mullite bricks in their melting furnaces, the service life of the furnace lining increased from 1 - 2 years to 3 - 4 years, reducing the frequency of furnace repairs and maintenance and increasing overall production efficiency by about 15%.

In the ceramics industry, these bricks are used in ceramic kilns. They provide stable support for ceramic products during the firing process. A ceramics factory in Asia found that using sintered mullite bricks in their kilns improved the quality of their ceramic products due to more uniform temperature distribution. The rejection rate of products decreased from 8% to 3%, resulting in significant cost savings.

In the metallurgy industry, sintered mullite bricks are used in steel - making ladles and non - ferrous metal smelting furnaces. They can resist the erosion of molten metal and slag. A steel plant in South America reported that the use of sintered mullite bricks in their ladles extended the ladle's service life from 80 - 100 heats to 120 - 150 heats, reducing the cost of ladle lining replacement.

If you're in the glass, ceramics, metallurgy, or other high - temperature industries and looking for a reliable refractory material, sintered mullite bricks are the ideal choice. Contact us today to learn more about our sintered mullite bricks. You can also request a free sample to test their performance in your specific application. Our expert team is ready to provide you with professional advice and support.

Contact Us