Sintered mullite bricks have become a cornerstone in the field of high-temperature refractory materials due to their exceptional thermal stability, mechanical strength, and long service life. As industrial processes continue to push the limits of temperature and durability, selecting the right refractory material is critical for operational efficiency and cost control.

In modern manufacturing, especially in sectors like steelmaking, glass production, and ceramics, refractory materials must withstand extreme temperatures—often exceeding 1,400°C—and resist chemical erosion, thermal shock, and mechanical wear. According to industry reports, over 70% of refractory failures are attributed to improper material selection or suboptimal firing processes.

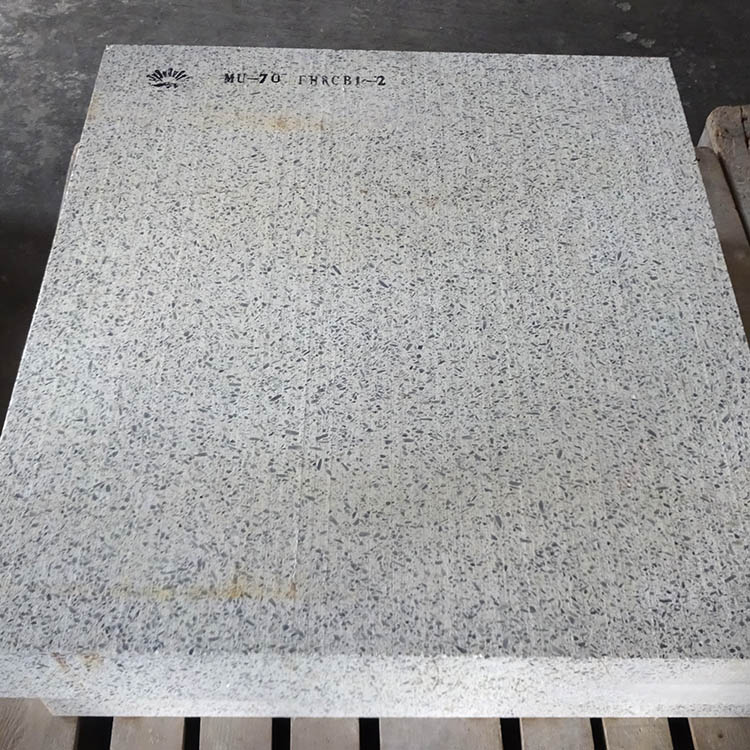

Sintered mullite bricks are a type of high-alumina refractory material composed primarily of mullite (3Al₂O₃·2SiO₂), which forms during the sintering process at high temperatures. They are classified based on their alumina content, with common grades ranging from 65% to 85% Al₂O₃. These bricks offer superior thermal shock resistance compared to traditional fireclay bricks and are widely used in high-temperature zones of furnaces and kilns.

The quality of sintered mullite bricks starts with the raw materials. Two primary components are used: synthetic mullite clinker and high-aluminum bauxite clinker. Synthetic mullite provides consistent microstructure and enhanced thermal stability, while high-aluminum bauxite contributes to better mechanical strength and chemical resistance. A typical composition might include 75% synthetic mullite, 20% high-aluminum bauxite, and 5% additives for improved sintering behavior.

The sintering process is crucial for developing the final properties of mullite bricks. During firing, the raw materials undergo phase transformations that increase density, reduce porosity, and enhance thermal conductivity. Standard firing temperatures range between 1,600°C and 1,750°C, ensuring optimal structural integrity. Data from leading manufacturers show that properly sintered mullite bricks can achieve a bulk density of up to 2.8 g/cm³ and a porosity below 18%.

Sintered mullite bricks are extensively used in various high-temperature industrial applications:

For example, a major glass manufacturer in Europe reported a 25% increase in furnace lifespan after switching to high-performance sintered mullite bricks.

When choosing refractory materials, consider factors such as operating temperature, chemical environment, and mechanical stress. It’s also important to evaluate the supplier’s technical support, product consistency, and compliance with international standards like ISO 10313. A reliable partner can provide tailored solutions based on your specific process requirements.

Discover how our high-quality sintered mullite bricks can improve your production efficiency and reduce maintenance costs. Our team of experts is here to help you make the best choice for your industrial needs.

Explore Our Products Now