When it comes to choosing refractory materials, many customers face a myriad of confusions. The high - temperature environment in industrial applications demands materials that can withstand extreme conditions, and mullite bricks have emerged as a popular choice. In this article, we'll delve into two main types of mullite bricks: sintered mullite bricks and fused - cast mullite bricks.

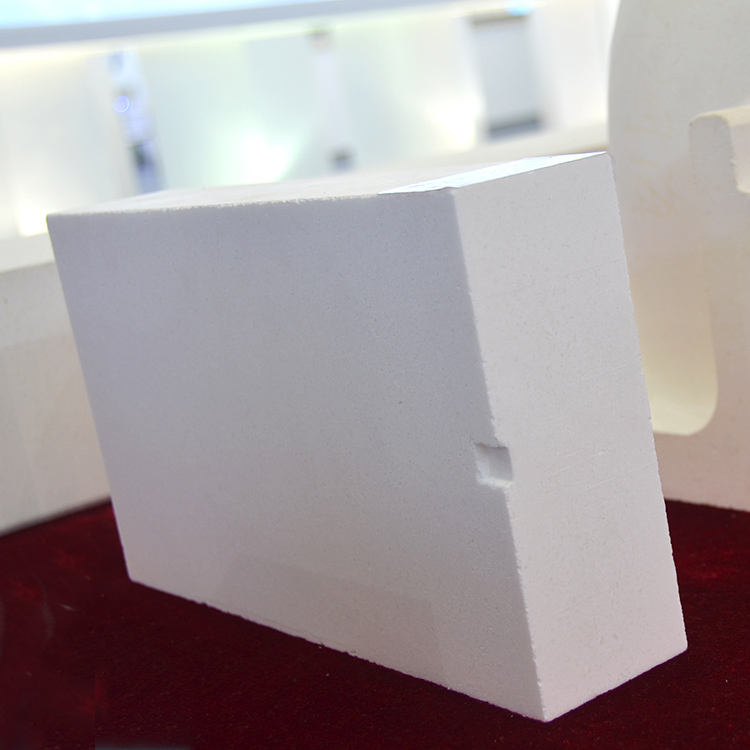

Sintered mullite bricks are crafted from synthetic mullite clinker and high - alumina bauxite clinker. The manufacturing process starts with careful ingredient mixing. After that, the mixture undergoes high - pressure molding to form the basic shape of the bricks. Finally, these molded bricks are fired at a temperature above 1600°C. This high - temperature firing process gives sintered mullite bricks excellent refractoriness, with a refractoriness under load (RUL) typically around 1500 - 1600°C.

These bricks also possess good thermal shock resistance. They can endure rapid temperature changes without significant damage, which is crucial in many industrial processes where temperature fluctuations are common.

Fused - cast mullite bricks are produced through an electric melting process. The raw materials are melted in an electric furnace at extremely high temperatures, usually around 2000 - 2200°C. Once melted, the liquid material is cast into molds and then cooled slowly. This results in a dense and uniform structure.

Fused - cast mullite bricks have a high density, typically around 2.8 - 3.2 g/cm³, and excellent corrosion resistance. They can resist the erosion of various slags and molten metals, making them suitable for harsh industrial environments.

| Properties | Sintered Mullite Bricks | Fused - Cast Mullite Bricks |

|---|---|---|

| Refractoriness | 1500 - 1600°C | Above 1700°C |

| Thermal Shock Resistance | Good | Relatively Lower |

| Density | 2.3 - 2.6 g/cm³ | 2.8 - 3.2 g/cm³ |

| Corrosion Resistance | Moderate | Excellent |

Metallurgy Industry: In the steel - making process, sintered mullite bricks can be used in the lining of ladles due to their good thermal shock resistance. Fused - cast mullite bricks, on the other hand, are often used in the troughs and runners for molten steel because of their high corrosion resistance.

Glass Industry: The high - temperature environment in glass furnaces requires refractory materials with excellent refractoriness. Sintered mullite bricks can be applied in the upper part of the furnace, while fused - cast mullite bricks are suitable for the areas in contact with molten glass.

Ceramics Industry: In ceramic kilns, sintered mullite bricks are commonly used as kiln furniture due to their good thermal stability. Fused - cast mullite bricks can be used in the parts of the kiln where high - strength and corrosion - resistant materials are needed.

In conclusion, both sintered and fused - cast mullite bricks have their unique properties and application scenarios. Sintered mullite bricks are known for their good thermal shock resistance and are more cost - effective, while fused - cast mullite bricks offer excellent corrosion resistance and high refractoriness.

At [Company Name], we understand that every customer's needs are different. That's why we offer a wide range of mullite brick products to meet your specific requirements. Whether you need sintered mullite bricks for their thermal shock resistance or fused - cast mullite bricks for their corrosion - resistant properties, we have the right solution for you.

Contact us today to discuss your refractory material needs and let our experts help you select the most suitable mullite bricks for your industrial applications!