In high - temperature industrial applications, the demand for reliable refractory materials is constantly growing. Traditional refractory materials often face challenges such as easy damage, short service life, and inability to withstand extreme temperatures. This is where sintered mullite bricks come into play, emerging as a superior solution in the high - temperature industrial landscape.

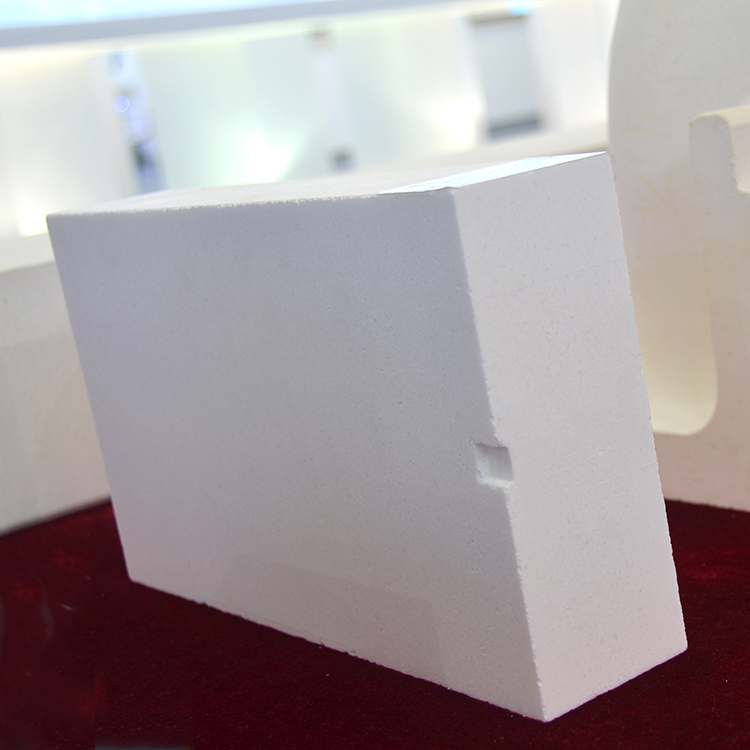

Sintered mullite bricks are high - alumina refractory products with mullite as the main crystalline phase. The unique crystal structure of mullite provides these bricks with excellent thermal stability and mechanical strength. Unlike ordinary refractory materials, sintered mullite bricks can maintain their integrity and performance under harsh high - temperature conditions.

These bricks are made from synthetic mullite clinker and high - alumina bauxite clinker. Synthetic mullite clinker has a high purity and a well - controlled crystal structure, which contributes to the overall quality of the bricks. High - alumina bauxite clinker, on the other hand, is rich in alumina, providing high refractoriness and resistance to chemical corrosion. The combination of these two high - quality raw materials gives sintered mullite bricks their outstanding properties.

Sintered mullite bricks are fired at temperatures above 1600°C. This high - temperature firing process is crucial for the formation of a stable crystal structure and the improvement of the brick's overall performance. During the firing process, the raw materials undergo a series of physical and chemical changes, resulting in a dense and uniform structure. This dense structure enhances the brick's resistance to heat, abrasion, and chemical attack. According to industry research, bricks fired at such high temperatures can have a service life that is 30% longer than those fired at lower temperatures.

Sintered mullite bricks have a wide range of applications in various high - temperature industries:

Our company has years of experience in the production of sintered mullite bricks. We adhere to strict quality control standards, ensuring that each brick meets the highest performance requirements. Our products are not only of high quality but also offer excellent cost - effectiveness. We have a professional technical team that can provide customized solutions according to your specific needs.

If you are in the high - temperature industry and looking for a reliable refractory material, our sintered mullite bricks are the perfect choice. Don't miss out on the opportunity to improve your production efficiency and reduce costs. Contact us today for more information or to request a sample. Our team is ready to assist you!

Contact us: [Contact Email/Phone Number]