In today's highly competitive glass industry, manufacturers are constantly grappling with rising production costs. Energy consumption, raw material prices, and equipment maintenance all contribute to the financial burden. However, there's a practical solution that can help glass enterprises cut costs and boost efficiency: siliconite shaped products.

Siliconite shaped products offer three core features that are directly linked to cost - saving:

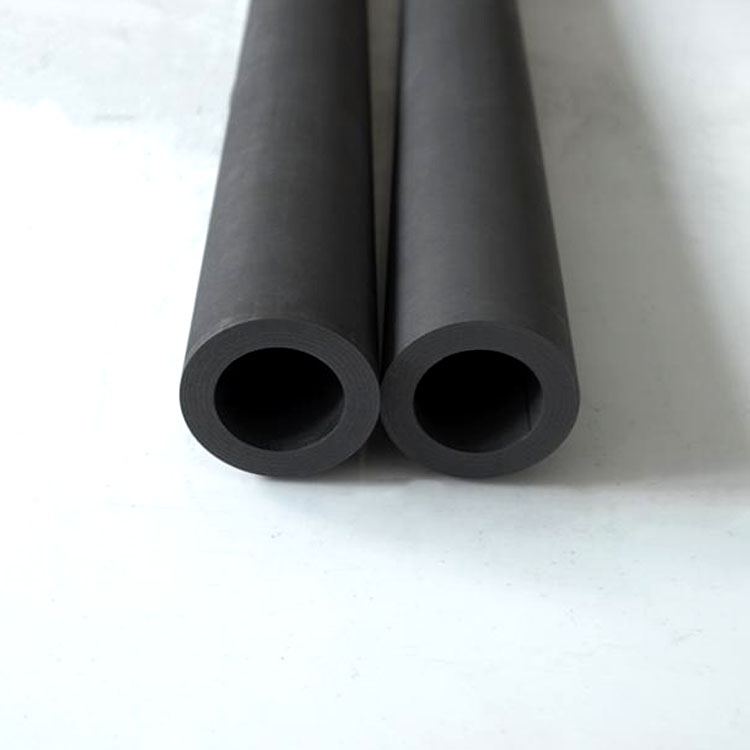

Siliconite shaped products come in various forms, each with its unique application value in glass production:

| Product Form | Application in Glass Production | Cost - Saving Benefit |

|---|---|---|

| Nozzles | Used in the glass - feeding system to control the flow of molten glass | Extended service life reduces replacement frequency and maintenance costs |

| Nozzle Rings | Provide support and sealing for nozzles | Improved erosion resistance decreases the need for frequent replacement |

| Stirrers | Mix molten glass to ensure uniformity | Longer lifespan means less downtime for replacement and maintenance |

When compared with traditional materials like corundum and silicon carbide, siliconite shaped products have significant advantages. In terms of service life, traditional materials may need to be replaced every 1 - 2 years, while siliconite products can last 3 - 4 years. This results in a substantial reduction in maintenance costs. A comparison bar chart can clearly show these differences:

| Material | Service Life (Years) | Maintenance Cost ($ per Year) |

| --- | --- | --- |

| Corundum | 1 - 2 | 5000 - 8000 |

| Silicon Carbide | 1 - 2 | 4500 - 7500 |

| Siliconite | 3 - 4 | 2000 - 3000 |

Let's look at some real - world examples. One glass manufacturer switched to siliconite shaped products for their feeding system. After implementation, the equipment replacement cycle was extended by 30%, from 2 years to 2.6 years. Additionally, maintenance man - hours were reduced by 40%, from 200 hours per year to 120 hours per year. Another customer reported similar results, with a significant reduction in overall production costs.

"Since we started using siliconite shaped products, we've seen a remarkable improvement in our production efficiency and a substantial reduction in costs. It's truly a game - changer for our business." - A satisfied customer

If you're looking to cut costs and improve efficiency in your glass production, siliconite shaped products are the answer. Let every dollar count and save on operating expenses from the source. Contact our technical team today at CTA - URL to get a customized solution tailored to your specific needs.