Mullite bricks have long stood as a cornerstone in the realm of high-alumina refractory materials — prized especially within the steel and metallurgy industry. Their exceptional thermal stability, robust structure, and chemical resistance make them the go-to choice for critical linings in furnaces, converters, and steel ladles. This article delves into the definition, production process, and practical applications of sintered mullite bricks, empowering industrial professionals to make informed, performance-driven refractory selections.

Mullite bricks are refractory components primarily composed of the mineral mullite (3Al2O3·2SiO2), valued for its high melting point (~1840°C), excellent resistance to slag corrosion, and minimal thermal expansion.

Within industrial settings, two main types dominate: sintered mullite bricks and fused mullite bricks, each with distinct manufacturing techniques and properties that impact performance and durability.

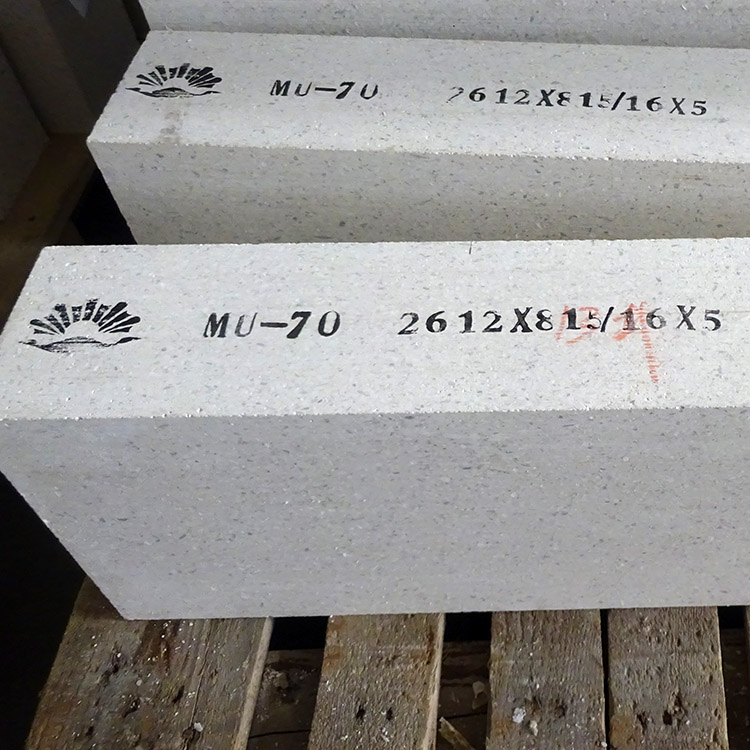

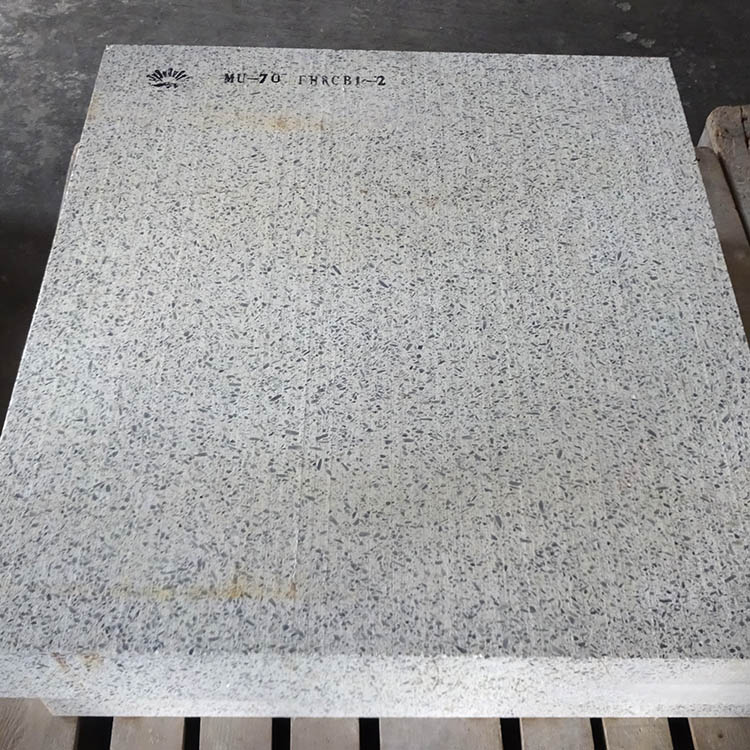

Sintered mullite bricks are produced by blending synthetic mullite clinker with high-alumina bauxite, then subjecting the mix to high-pressure molding followed by sintering at temperatures exceeding 1600℃, often reaching 1700℃. This process yields superior microstructure uniformity and structural integrity. In contrast, fused mullite bricks are formed by melting raw materials at temperatures above 1900℃ using electric arc technology, then cast into molds.

Technically, sintered mullite bricks bring benefits such as:

The production of sintered mullite bricks involves several critical steps:

This process results in bricks exhibiting excellent thermal stability, low creep, and outstanding resistance against chemical and mechanical wear—crucial traits for refractory linings in demanding steelmaking environments.

Several leading steel plants report remarkable performance improvements following the adoption of sintered mullite bricks in refractory linings:

These case studies are corroborated by industry reports indicating sintered mullite bricks maintain structural integrity even after prolonged exposure to temperatures surpassing 1600°C and aggressive slag environments.

For professionals striving to optimize furnace longevity and operational efficiency, sintered mullite bricks stand as the logical choice. Their proven ability to withstand thermal shock, reduce wear rates, and lower maintenance frequency directly translates into higher uptime and cost savings.

Integrating sintered mullite bricks into your refractory portfolio is a strategic investment that maximizes furnace life cycles and fosters predictable maintenance scheduling—essential factors for competitive steel production.

We invite your thoughts: What challenges have you faced in refractory material selection for steelmaking? Share your experiences below and join the conversation.