If you're responsible for kiln design, maintenance, or procurement in ceramics, glass, or metallurgy, choosing the right mullite brick can make or break your process efficiency—and your bottom line. Both burned and electrofused mullite bricks are high-performance refractories, but they differ significantly in production, performance, and cost-effectiveness.

Mullite (3Al₂O₃·2SiO₂) is a key component in high-alumina refractory materials used above 1200°C. According to GB/T 2947-2012, mullite bricks offer excellent thermal shock resistance, low creep, and strong chemical stability—making them ideal for kilns operating under extreme conditions.

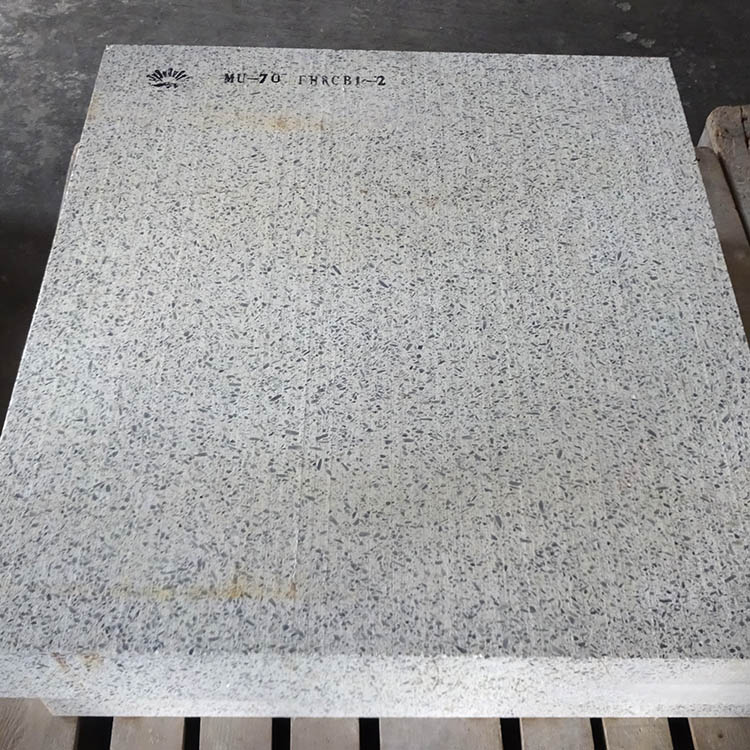

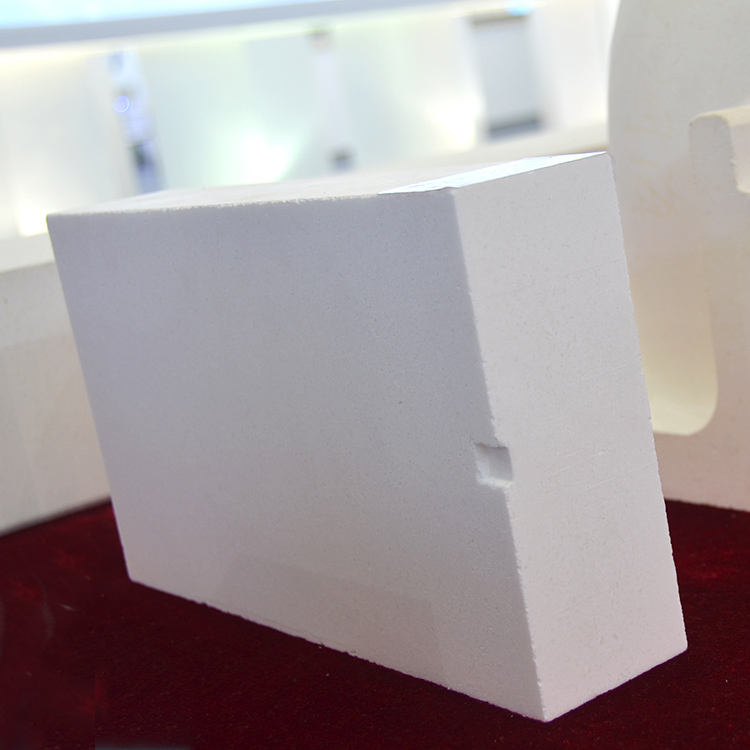

Burned mullite bricks are made by mixing raw alumina and silica powders, pressing into shapes, and firing at 1600–1700°C. This creates a microstructure with fine-grained mullite crystals embedded in a glassy phase. In contrast, electrofused mullite bricks melt pure raw materials in an electric arc furnace (>2000°C), forming large, interlocking mullite crystals that enhance structural integrity.

In practical kiln environments—especially those with frequent temperature cycling—burned mullite bricks outperform their electrofused counterparts due to superior thermal shock resistance. Field tests show a 30% longer service life when used in tunnel kilns operating between 1100–1500°C, compared to electrofused bricks that crack more easily under rapid heating/cooling cycles.

Plus, burned mullite offers better construction adaptability: it’s easier to cut, drill, and install without chipping—a critical factor during retrofitting or repairs. And while electrofused bricks may have slightly higher density (3.0–3.2 g/cm³ vs. 2.8–3.0 g/cm³), the price premium isn’t always justified unless your kiln runs continuously at >1700°C.

A study from a ceramic manufacturer in Italy found that switching from electrofused to burned mullite bricks reduced annual refractory replacement costs by 28%, even after accounting for minor differences in installation time. That’s not just savings—it’s operational continuity.

So, if your kiln operates below 1700°C, has variable loads, or experiences frequent startups/shutdowns—choose burned mullite. It’s not just about saving money—it’s about reducing downtime, improving safety, and optimizing energy use.

Whether you’re designing a new kiln or maintaining an existing one, selecting the right mullite brick is a smart investment—one that pays off in durability, efficiency, and peace of mind.

👉 Choose Burned Mullite Bricks for Long-Lasting Kiln Performance

Get a free technical consultation tailored to your kiln’s specific operating conditions.

What’s your biggest challenge with refractory selection? Share your experience in the comments—we’ll help you find the best fit for your application.