In industrial production, especially in high - temperature environments such as those in the steel industry, traditional refractory materials often face significant challenges. Under extreme heat conditions, they can easily crack, erode, or lose their structural integrity. For example, in steelmaking furnaces where temperatures can reach up to 1600°C, common refractory bricks may only last for about 3 - 6 months before needing replacement. This not only leads to increased maintenance costs but also causes production interruptions, which can be a major headache for industrial operators.

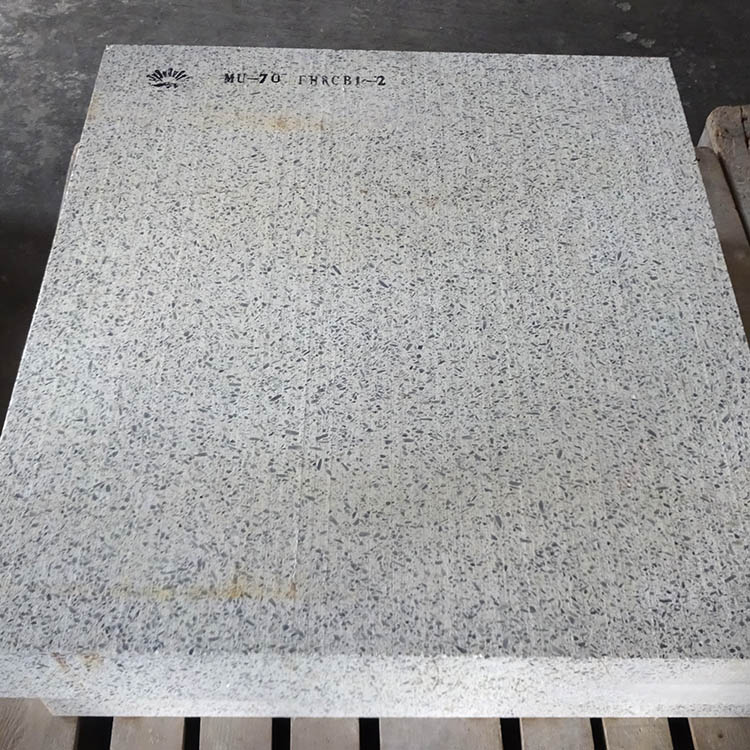

Sintered mullite bricks are high - alumina refractory products with mullite as the main crystalline phase. There are different types of sintering processes for these bricks, which play a crucial role in determining their final properties. The sintering process helps to enhance the density and strength of the bricks, making them more resistant to high - temperature environments.

The two main raw materials for sintered mullite bricks are synthetic mullite clinker and high - alumina bauxite clinker. Synthetic mullite clinker has a high purity of mullite phase, typically over 90%. It provides excellent thermal stability and resistance to chemical corrosion. High - alumina bauxite clinker, on the other hand, is rich in alumina content, usually around 80 - 85%. This high alumina content contributes to the high - temperature strength and abrasion resistance of the bricks. Together, these two raw materials ensure the high - quality performance of sintered mullite bricks.

The high - temperature firing process is a key step in the production of sintered mullite bricks. When the firing temperature is around 1500°C, the bricks have a relatively lower density and strength. However, when the firing temperature reaches 1700°C, the density of the bricks can increase by about 10 - 15%, and the compressive strength can increase by up to 30 - 40%. This significant improvement in performance is due to the complete crystallization and densification of the mullite phase at higher temperatures.

Sintered mullite bricks have been widely used in various industries. In the steel industry, they are used in blast furnaces, ladles, and other high - temperature equipment. For example, a steel plant in Europe replaced their traditional refractory bricks with sintered mullite bricks in their ladles. The service life of the ladles increased from 50 - 60 uses to over 100 uses, significantly reducing the maintenance cost and downtime. In the glass industry, sintered mullite bricks are used in the melting furnaces. They can withstand the high - temperature and corrosive environment of the glass - melting process, ensuring the stable operation of the production line.

If you are in the consideration stage of purchasing refractory materials, sintered mullite bricks are an excellent choice. Their high - temperature resistance, long service life, and cost - effectiveness make them a reliable solution for your industrial needs. Don't miss out on this opportunity to enhance your production efficiency and reduce costs.

Contact us today to learn more about our sintered mullite bricks! You can also request a free sample to test its performance in your own environment. Click here to get in touch or send an email to [email protected].