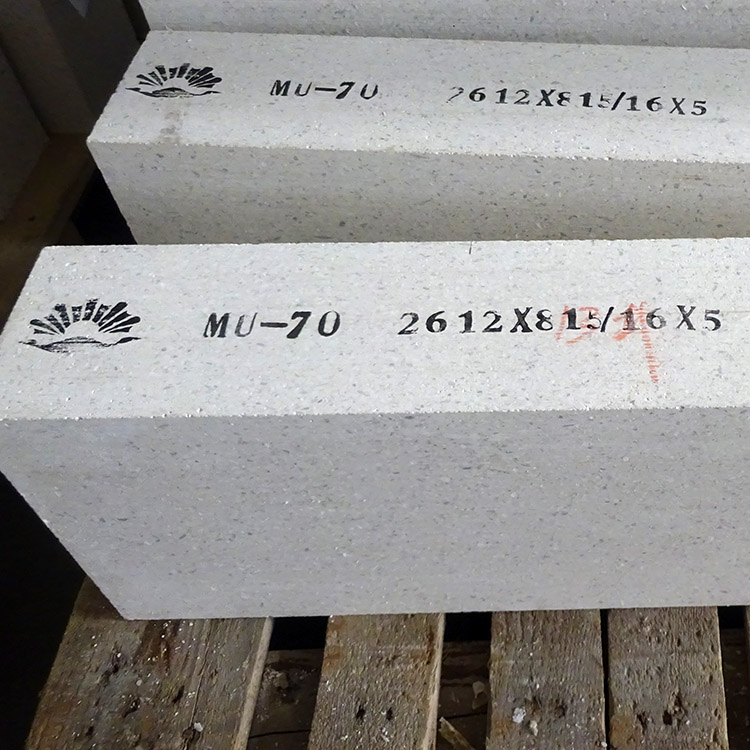

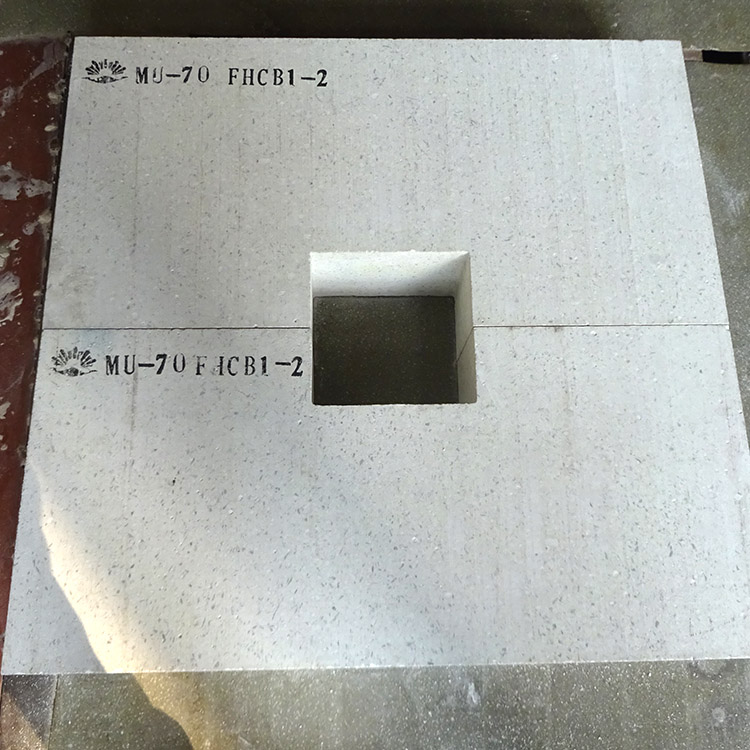

Industrial applications in high-temperature environments demand materials that can withstand extreme conditions without compromising performance. Among the most reliable solutions is sintered mullite bricks, a high-alumina refractory product known for its exceptional thermal stability and durability. These bricks are primarily composed of mullite as the main crystalline phase, making them ideal for use in furnaces, kilns, and other high-heat industrial equipment.

Sintered mullite bricks are manufactured using two key raw materials: synthetic mullite clinker and high-aluminum bauxite clinker. These materials are processed at temperatures exceeding 1600°C, resulting in a highly stable microstructure and superior refractory properties. Compared to traditional firebricks, sintered mullite bricks offer better resistance to thermal shock, lower porosity, and improved mechanical strength under high heat.

| Property | Sintered Mullite Bricks | Traditional Firebricks |

|---|---|---|

| Thermal Shock Resistance | High | Moderate |

| Porosity | Low (≤15%) | Higher (≥20%) |

| Compressive Strength | ≥120 MPa | ≤100 MPa |

| Operating Temperature | Up to 1700°C | Up to 1400°C |

The use of synthetic mullite clinker ensures a consistent and high-purity composition, which enhances the overall performance of the final product. This material is produced through controlled synthesis processes, eliminating impurities that could affect structural integrity. Similarly, high-aluminum bauxite clinker provides an excellent base for forming a strong matrix during the sintering process. Together, these components contribute to the long service life and reliability of sintered mullite bricks.

The firing process plays a crucial role in determining the quality of sintered mullite bricks. At temperatures above 1600°C, the raw materials undergo complete densification, forming a dense and homogeneous structure. This not only improves the brick's mechanical properties but also reduces the risk of cracking or deformation under prolonged exposure to heat. Studies have shown that bricks fired at 1650°C exhibit up to 20% better thermal stability than those fired at 1550°C.

Sintered mullite bricks are widely used across various industries, including cement production, glass manufacturing, and steelmaking. In one case study from a large-scale cement plant in Southeast Asia, the replacement of traditional firebricks with sintered mullite bricks led to a 30% reduction in maintenance costs and a 15% increase in furnace efficiency. Another example comes from a glass melting furnace in Europe, where the use of these bricks extended the lining life by over 40%, significantly reducing downtime.

If you're looking for a durable and high-performance alternative to traditional refractory materials, sintered mullite bricks are an excellent choice. With their proven track record in demanding industrial environments, they provide long-term value and operational efficiency. Whether you're upgrading existing systems or designing new high-temperature applications, our team is here to support you.

Explore our range of sintered mullite products today and discover how they can enhance your production processes. For more information, samples, or customized solutions, please contact us directly.

Request Sample or Consultation