In the global refractory materials market, with the continuous development of industries such as metallurgy, glass, and ceramics, the demand for high - performance refractory materials is also increasing. In this highly competitive market environment, mullite bricks have emerged as a star product, attracting the attention of numerous global purchasers.

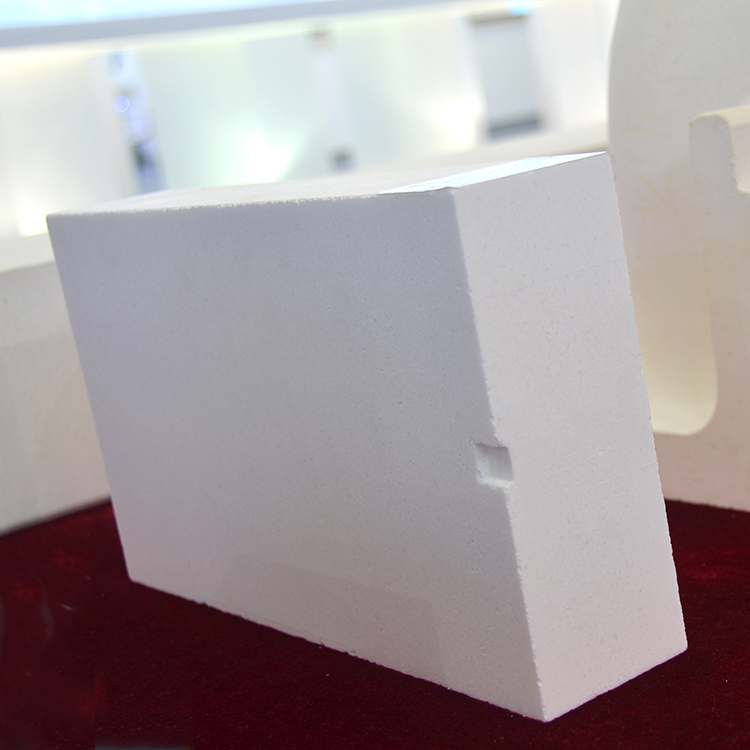

Mullite bricks are high - alumina refractory products with mullite (3Al₂O₃·2SiO₂) as the main crystalline phase. They are mainly divided into sintered mullite bricks and fused mullite bricks. Sintered mullite bricks are made from synthetic mullite clinker and high - alumina bauxite clinker, while fused mullite bricks are produced through an electric melting process. Each type has its own unique characteristics and application scenarios.

| Type | Production Process | Characteristics |

|---|---|---|

| Sintered Mullite Bricks | Made from synthetic mullite clinker and high - alumina bauxite clinker through processes of batching, high - pressure forming, and firing at a temperature above 1600°C. | Uniform structure, good thermal shock resistance, and high refractoriness. |

| Fused Mullite Bricks | Produced by electric melting process. | High density, excellent corrosion resistance, and good mechanical properties at high temperatures. |

The production of sintered mullite bricks is a complex and precise process. First, carefully selected synthetic mullite clinker and high - alumina bauxite clinker are used as raw materials. After accurate batching, they are subjected to high - pressure forming to ensure the compactness and uniformity of the green bricks. Then, the green bricks are fired at a temperature above 1600°C. This high - temperature firing process is crucial as it can significantly improve the refractory performance of the bricks.

According to industry research data, sintered mullite bricks fired at a temperature above 1600°C can have a refractoriness under load of up to 1650°C, and their thermal shock resistance can reach more than 20 times (1100°C water - cooling). These excellent performance indicators make them stand out in the refractory materials market.

In a large - scale steelmaking enterprise, sintered mullite bricks were used in the lining of the steelmaking furnace. After long - term use, it was found that compared with traditional refractory bricks, the service life of the furnace lining made of sintered mullite bricks was extended by 30%. This not only reduced the frequency of furnace lining replacement but also improved production efficiency and reduced production costs.

In the glass industry, fused mullite bricks are used in the melting tank of glass furnaces. Their excellent corrosion resistance and high - temperature mechanical properties ensure the long - term stable operation of the glass furnace, improving the quality and output of glass products.

Mullite bricks, whether sintered or fused, have excellent refractory performance, good thermal shock resistance, and strong corrosion resistance. Their well - crafted production process ensures product quality and stability. In the face of a wide variety of refractory materials on the market, mullite bricks are undoubtedly a reliable choice for global purchasers.

If you are looking for high - quality refractory materials, don't miss the opportunity to choose mullite bricks. Our company can provide you with professional products and services. Contact us now to learn more details!