In modern industrial production, the demand for high - performance refractory materials is constantly on the rise. Industries such as steel, glass, and cement require materials that can withstand extreme temperatures, chemical corrosion, and mechanical stress. These high - standard requirements have led to the development and application of advanced refractory products, among which sintered mullite bricks stand out.

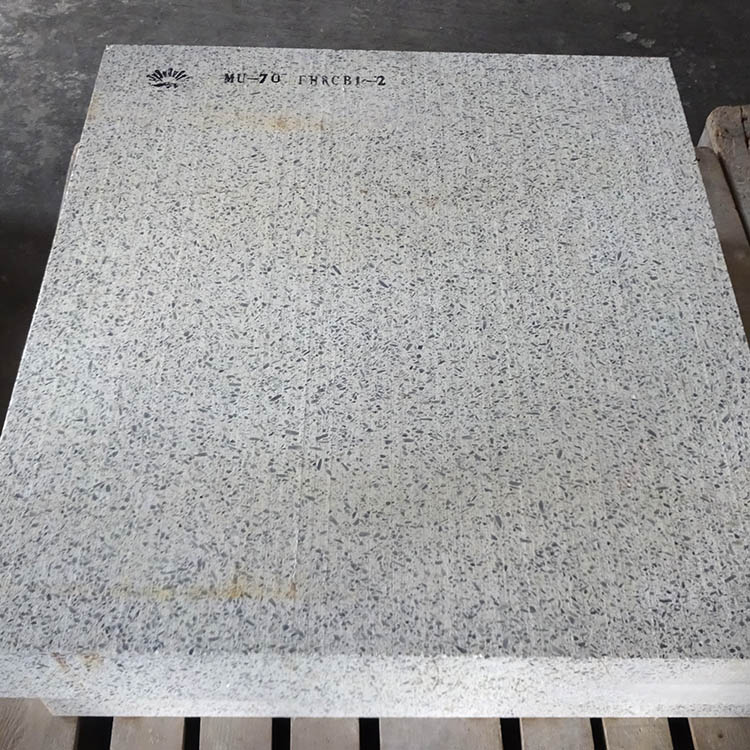

Sintered mullite bricks are a type of high - quality refractory product made from carefully selected raw materials through a series of strict manufacturing processes. They can be classified into different types according to their chemical composition, physical properties, and application scenarios. Generally, they can be divided into ordinary sintered mullite bricks, high - purity sintered mullite bricks, and special - purpose sintered mullite bricks.

Synthetic mullite clinker and high - alumina bauxite clinker are two key raw materials for sintered mullite bricks. Synthetic mullite clinker has a high content of mullite crystals, which endows it with excellent high - temperature stability, low thermal expansion coefficient, and good chemical resistance. In high - temperature environments above 1600°C, it can maintain its structural integrity and performance, effectively reducing the risk of cracking and deformation of the refractory product. For example, in some high - temperature furnaces, the use of synthetic mullite clinker can increase the service life of the furnace lining by about 30% compared with ordinary refractory materials.

High - alumina bauxite clinker, on the other hand, is rich in alumina, which gives it high strength and hardness. It can improve the mechanical properties of sintered mullite bricks, making them more resistant to abrasion and impact. In practical applications, high - alumina bauxite clinker - based sintered mullite bricks have been widely used in areas where mechanical stress is relatively large, such as the feeding area of steelmaking furnaces.

The high - temperature firing process is a crucial step in the production of sintered mullite bricks. Firing at temperatures above 1600°C can promote the formation of a dense crystal structure in the bricks, significantly improving their density, strength, and high - temperature performance. Studies have shown that when the firing temperature reaches 1700°C, the bulk density of sintered mullite bricks can increase by about 5%, and the compressive strength can increase by about 20% compared with bricks fired at lower temperatures. Moreover, high - temperature firing can also enhance the chemical stability of the bricks, making them more resistant to the erosion of molten metals and slag.

In the steel industry, sintered mullite bricks are widely used in the lining of steelmaking furnaces, ladles, and tundishes. Their excellent high - temperature performance and chemical resistance can effectively protect the furnace structure from the erosion of molten steel and slag, ensuring the smooth progress of the steelmaking process. For example, in a large - scale steel plant, after using sintered mullite bricks in the ladle lining, the ladle's service life has been extended from 80 times to more than 120 times, greatly reducing the maintenance cost and production interruption time.

In the glass industry, sintered mullite bricks are used in glass melting furnaces. Their low thermal expansion coefficient and good chemical stability can prevent the formation of cracks in the furnace lining and the contamination of the glass melt, improving the quality of glass products. In a glass factory, the application of sintered mullite bricks has reduced the defect rate of glass products by about 15%.

If you are looking for high - quality refractory materials for your industrial applications, our sintered mullite bricks are the ideal choice. With the use of advanced synthetic mullite clinker and high - alumina bauxite clinker, combined with strict high - temperature firing processes, our products can provide you with reliable high - temperature protection and long - term service. We invite you to click here to learn more about our products and services, or you can contact us directly to request product samples. Let us help you solve your refractory material problems and improve the efficiency and profitability of your industrial production.