In the dynamic landscape of the global refractory materials market, finding a reliable and high - performance solution is crucial for businesses across various industries. One such remarkable product that has been gaining significant attention is the mullite brick. Let's embark on a journey to uncover the secrets behind this exceptional high - alumina refractory product.

Mullite brick is a high - alumina refractory product with mullite (3Al₂O₃·2SiO₂) as the main crystalline phase. It has outstanding high - temperature resistance, excellent thermal shock resistance, and low thermal conductivity, making it an ideal choice for high - temperature industrial applications. According to industry data, mullite bricks can withstand temperatures up to 1800°C, ensuring stable performance in extreme environments.

Mullite bricks are mainly divided into two categories: sintered mullite bricks and fused mullite bricks. Each type has its own unique characteristics and applications.

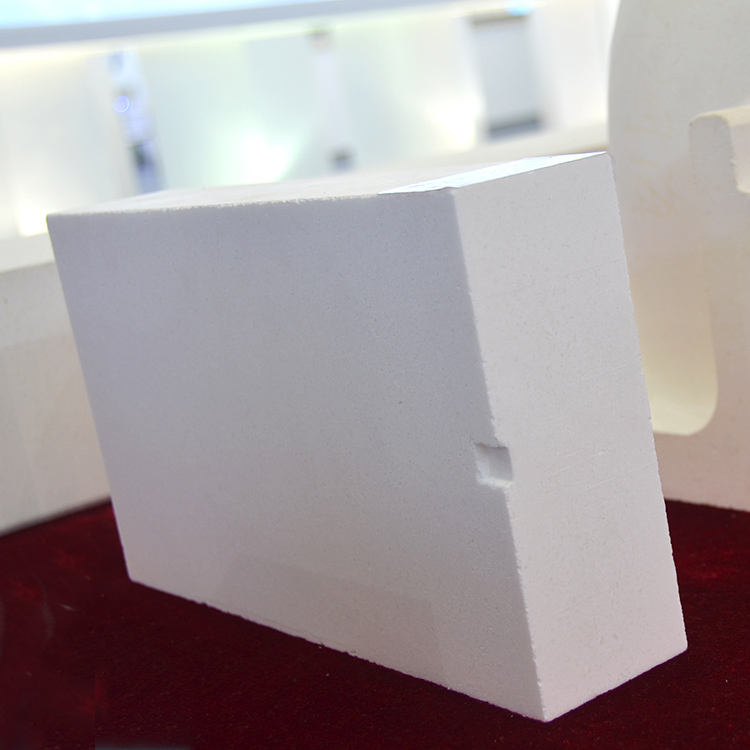

Sintered mullite bricks are made from synthetic mullite and high - alumina bauxite clinker. The manufacturing process involves precise batching, high - pressure molding, and firing at a temperature above 1600°C. This high - temperature firing process enhances the density and strength of the bricks, significantly improving their refractory performance. A research report from a well - known refractory materials institute indicates that sintered mullite bricks have a compressive strength of up to 100 MPa, which is much higher than many other refractory materials.

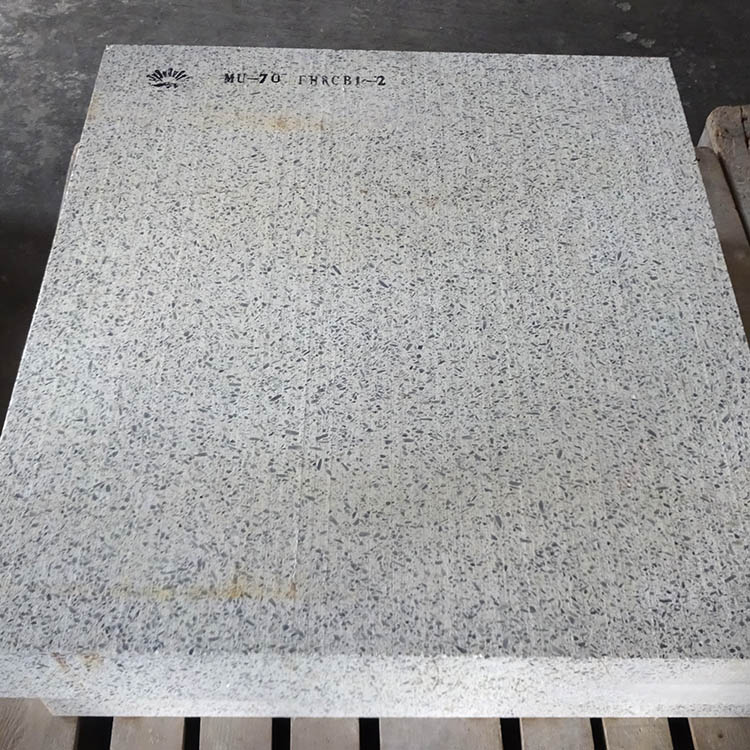

Fused mullite bricks are produced by melting raw materials in an electric arc furnace and then casting them into molds. These bricks have a more uniform structure and higher purity, providing better corrosion resistance and thermal stability. In some chemical plants, fused mullite bricks have been reported to extend the service life of furnaces by up to 30% compared to traditional refractory materials.

The excellent refractory performance of mullite bricks makes them widely used in various industries. In the steel industry, they are used in blast furnaces, ladles, and converters; in the cement industry, they are applied in rotary kilns; in the glass industry, they are used in glass melting furnaces. The following table shows some typical applications and performance requirements:

| Industry | Application | Performance Requirement |

|---|---|---|

| Steel | Blast Furnace | High Temperature Resistance, Corrosion Resistance |

| Cement | Rotary Kiln | Thermal Shock Resistance, Abrasion Resistance |

| Glass | Glass Melting Furnace | Low Impurity Content, High Thermal Stability |

Mullite bricks offer several advantages over other refractory materials. Their high - temperature resistance, excellent thermal shock resistance, and low thermal conductivity ensure long - term stability and energy efficiency in high - temperature applications. In addition, their superior corrosion resistance and mechanical strength reduce maintenance costs and downtime. When it comes to choosing a refractory material, mullite bricks should be your top choice.

Don't miss out on the opportunity to enhance your high - temperature operations with our high - quality mullite bricks. Contact us today to discuss your specific requirements and get a customized solution!